Step 1: Install Corel Draw 12, X4, X8 or similar version.

Step 2: Install CorelLaser

Open CorelLaser. You can use this template to start with, it has one engraving layer and one cutting layer.

When CorelLaser is installed you will find this menu.

Click on the green pen icon.

![]()

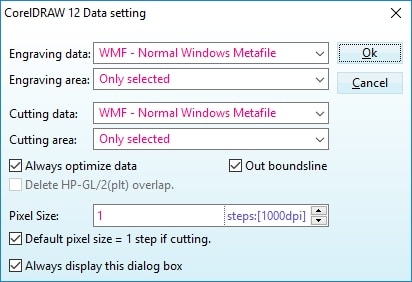

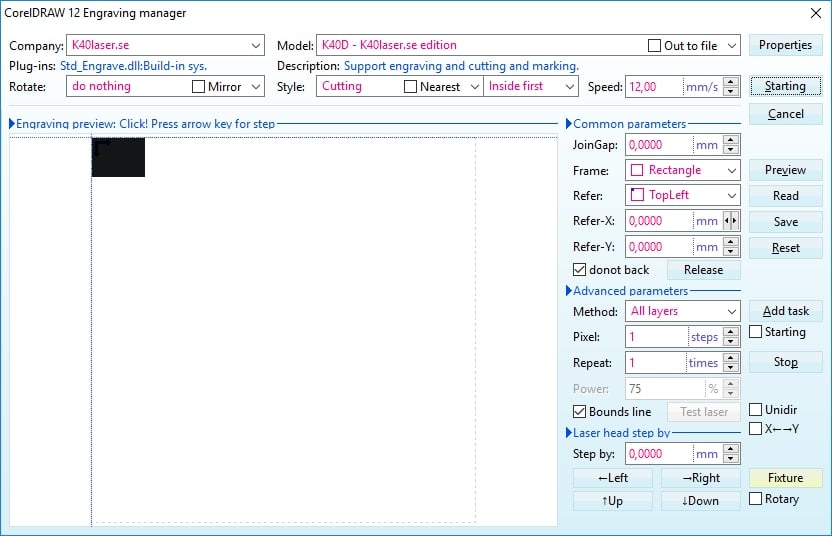

Control your settings so its identical to this screen.

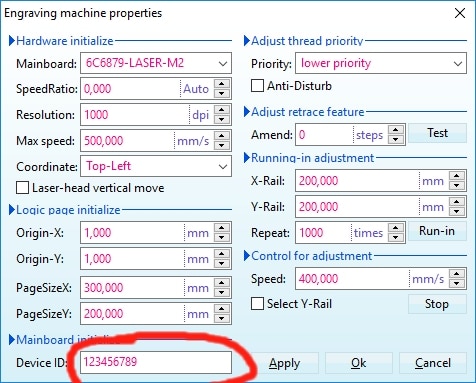

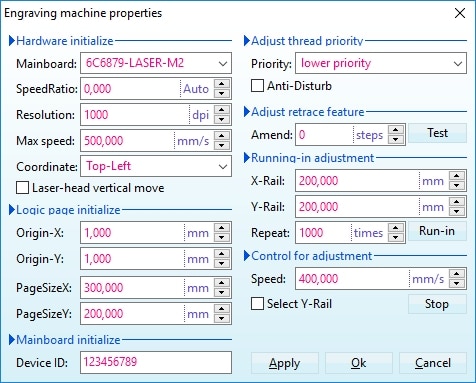

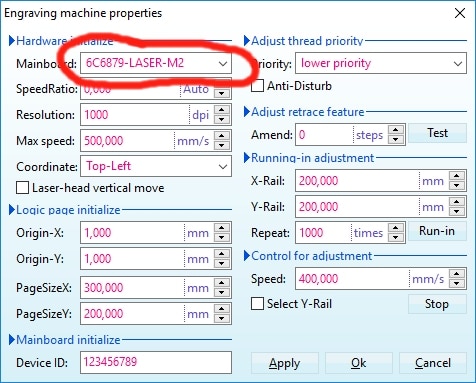

Most important setting is the mainboard, you may need to change this later if your machine operates very slow (a first sign of wrong mainboard selected)

You can find information about wich board you have on the controller board in your machine.

Next setting is to check your hardware device ID, you can find this on the controller board, se image below

Check out the other settings and make sure you have the same on your settings.

You are now ready to start your first test with the machine

Start with the “rectangle tool” in corel, make a box with the size of your choise, i made a 54x40mm box.

Select the box as shown in the picture, and in the top menu you see a line width set to “hairline”.

Change this to 0.001 and hit enter.

You are now ready for your first cut test.

Select CUT in the corel menu, the icon marked here

![]()

Click OK on the data setting, we did this in a earlier step.

Make sure the settings are still there.

Now you have this setup box (click to expand)

To explain some of the settings

Company and model is just the data about your machine.

Rotate: if you need to rotate or flip your design for mirrored cut/engravings.

Style: Cutting, engraving and marking. For this test we choose CUTTING.

Inside first is a good option if you make parts, the machine will cut the inner parts first and then the outer, preventing the part to fall down without the inner holes are cut.

Speed: I have a 3mm acrylic piece in my machine, you may have to test the speed and the power on your machine when testing your cut.

I would suggest 12mA power and 10mm/sec to start with.

Method: If you have combined engraving and cut in the same file, you can choose here.

In the template before, we split engraving and cut in two different layers, this will help you to run the engraving first, and cut later.

Pixel: set this to 1 step, and Repeat to 1 times

You are now ready to hit STARTING

More tips and tricks

Test similar design to learn how power and speed relates on your machine, this is different on most K40 and you cannot use the same settings someone else has. You need to find your optimal combo.

cheers found your instructions very helpful and got us up and running

Hi, what’s wrong? “Device id is changed, please exit the software and restart to use new ID.

I have do this. But I cant set data to the laser.

Read the ID on the controller board and set it in the software. And choose the correct mainboard. You might need to test different mainboards until you find one that works for you – if the laser moves super slow, try another one.

If you still have the Devide-id error, remove all software, reboot the computer and install it again.

Thank you, I have don this all. The laser never works. The software is new after restart. I have write the 16 Code vom Mainbord into device-id.

Its allways error, answer I need a new Devide ID.

Have you plugged the USB in to your computer? This is a hardware lock and has to be in the computer and the drivers installed.

You can find the drivers here: https://k40laser.se/k40drivers.zip – run setup.exe and follow instructions – do this with the machine OFF and disconnected, and corellaser/corel not started.

Reboot the computer after you install – and after test the machine again.

If it still does not work – test with K40 Whisperer software (find on google), it bypasses the hardware lock.

When I power the unit up it goes to the upper right hand corner and vibrates as if it is trying to go farther. We didn’t realize that the ribbon cable wasn’t connected to anything. I connected it where it should go and now it does what I said

If it still goes right, its a sign that the end-stops doesnt register properly. Check the cables on the end-stops. Double check that the ribbon cable is in the correct orientation.

It should home to top left.

Hi, not sure what I’m doing wrong here. Setup the software and trying to engrave. I can see the laser head moving, but not doing anything, really, as is nothing is being engraved. Please are you able to help? Thank you.

Start with this article and follow the steps -> https://k40laser.se/diy-how-to/no-fire-troubleshooting/

Hello sir… my machine is very slow when engraveing. Can you help me?

Change mainboard in the settings of your software, when you have the correct mainboard it will be fast.

Is there anyway to adjust the thickness of the material it will cut? I have wood that is 3.302mm thick, but it wont cut, just engrave.

You need to move the bed lower and then use scrap pieces to lift the material to correct height.

Read this article: https://k40laser.se/diy-how-to/setting-the-proper-focus-in-your-k40/

I installed the Corel draw that was on the cd that came with the k40 but it asked for a key code to install but I can’t find a key code anywhere on the cd or in any of the programs on the cd. Where did y’all get the code key or Corel draw without paying big bucks?

Most corel versions are cracked and do not need a serial at all. Do not upgrade the version you install, it will need a legit serial if you do.

Without the key code it won’t let me go any further

The serial number is buried on the cd. On mine the file is called sn.txt

Hi

A query about setup material in laser in sync with computer drawing if that makes sence

IE where to put matererial in laser so that the drawing starts at same place on meteria as computer kind regards rogar1

For pens, and other stuff i need to engrave on both sides i use jigs. And in the corder of the bed i have a L-shape where the jigs are “zeroed”. I cut the hole in the jig and then use the same template to know where to put text or symbols to engrave on the pieces. Check out the facebook-group and serch for jigs and youll see a bunch of examples.

Hi

Feeling like an exhausted and frustrated idiot at the moment, and this is the first of what feels like a million searches that actually makes sense! So thanks!

I do laser engraving on wooden items.

Everything was working nicely with CorelDRAW 12 all set up, file new; file import; laser running; start! All good!! Now I’ve had to replace machine… so everything’s the same set up in corelDraw, but coming out as just badly burnt lines. Please help me??

Make sure you are properly set in focus, to me it sounds like you are either too close or to far away. check out the article about proper focus.

hallo My k40 cut and engrave bigger than the actual drawing and i dont know how to fix it …Any ideea what i do wrong ?

Try to change the mainboard to something else, when it stops doing this – you have the correct board choosen. Other problems might be it running very slow on the wrong mainboard.

When i first made a cut part with my K40 laser it also came out bigger. I had to change the resolution to1002. That made the parts come out the correct size.

Did you create the file in inkscape? newer versions of inkscape has changed the DPI settings, so some stuff might be larger than it should be. Google for “inkscape wrong dpi” to find more and how to solve it.

I had no idea that you needed to consider the pixel when looking into laser cutting. It is important to remember that doing some research can help you understand how laser cutting works in order to get the best results. A friend of mine was talking about how he wanted to do some laser cutting, so I wanted to look into it for him.

Hi! I just recently bought a K40 and what I’ve observed is that my machine seems to cut vertically without any problems. Horizontally however the machine pretty much refuses to do anything, even on cardboard at 50% power at 10mm/s. The machine itself seems pretty weak to begin with. Have you experienced this before?

Luca

Make sure the laser is aligned properly, if you hit a edge on the mirrors or on the lens you will lose a lot of power. Try that first!

hello,

Your explanation about the laser was very helpful. But I have a doubt about few parametes. What does it mean by pixel in the software? Is there any relation between the pixel and the DPI?

It´s a bit diffuse, it can be used to interpret 2 or more pixels per motor step, which will make the outcome smaller, or leave bigger gaps in engravings. I have not tested this enough to know exactly what it does when cutting/engraving.

A pixel is a single dot in an image. It can be of any color. DPI or Dots Per Inch is a measure of how many pixels (dots) are found in a single linear inch. So, for example, 300 DPI has 300 pixels in that inch.

hello, i have some problem with the setup of software. when i first connected the printer (just the electricity) my laser boot up and went to the origin (when there are the limit switches top-left). all normal but when i go inside the software and say inizialize machine it start going on bottom right corner searching for i think limit switches. i checked my parameters and they are all ok, do you have some suggestions?

the laser when i inizialize the machine go for some time at nearly 45° than he rapid for like 5 cm to the right and it stopped.

Make sure the end stops work, try activating them before the gantry goes to top left corner and see if it stops. Also check the cables to the end stops.

found the problem. was a faulty connection of the main power supply to the board. i just rebuild the cable and now is fine

Hi Mirko ,

I have the same problem , can you send me one photo of cable ?

Regards.

Hi. My k40 does what it wants could really do with some help when I switch it on it stops somewhere different every time and makes a hell of a clattering noise .

I only just bought it and I am beginning to think it’s a duff one ….any ideas please .

Check out this article. https://k40laser.se/diy-how-to/k40-machine-stops-before-job-is-done-fixes-and-issues/

Another issue might be the speed, slow down it you are above 200mm/s.

Thank you so much. This fixed all of my issues I was having!!

Hi HP – I installed CD12 but CL gives me error message “The Corel Draw (ver>=11) software not installed”

Download K40 Whisperer instead, easier to get going with.