I personally coined the expressions “smoke assist” a year ago when i was trying to explain to new users what the difference is on air assist and smoke assist, and what the two different techniques should be used for 🙂

What is smoke assist?

Smoke assist is a helping hand to keep your mirror or/and lens clean of the smoke generated by the lasing work.

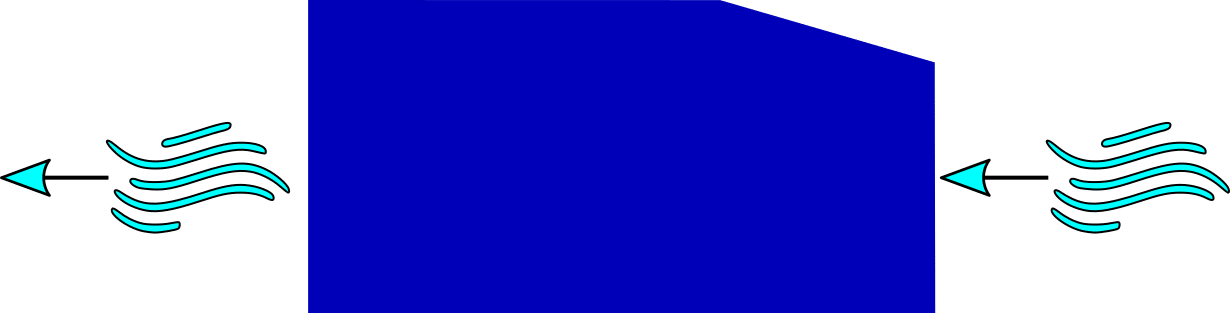

The exhaust should only do the work of transporting the smoke from the exit to the end of the hose, nothing else.

The smoke assist helps moving the smoke from the cut area to the exit where the exhaust fan takes over.

With the smoke assist you can use less powerful exhaust fans, as the exhaust doesnt need to put the machine casing under negative pressure to clean out the smoke, the smoke assist helps with this.

Common airflow and air dynamics, what you want is a flow trough the machine with air, from the smoke assist fans -> exhaust fan.

Easiest solution for a smoke assist

Add fans, doesn´t matter what fans, i used my daughters hair dryer the first weeks and later changed to two 50mm 12v DC fans mounted in the front of the machine blowing air over the bed.

Later on i added more fans inside the machine on my laser head to keep the lens clear.

For bigger machines you need bigger fans, like 120mm computer fans.

This laser head is custom made by me, not a original product.

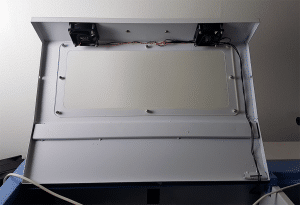

Here is the intake fans in my lid. You can mount them in the bottom or front piece, just add fans to help out with the input of air.

ADVERTISING

Cloudray Co2 Laser Tube 700MM 40W

Cloudray Co2 Laser Tube 700MM 40W

Could you technically run two air pumps and get the same effect? Like have a 60L/min pump mounted in front and blow in air and have a small fan push it towards the back of the case towards the exhaust?

Sure, it´s all about turbulence and pressure differences. If you push in air you get turbulence. If you have a 3D-printer you can test with different nozzles on the end of the hose from the air compressor to see what kind moves air the best.

I´m using a fog-machine now, but incense sticks or mosquito things you light up works too so you can see how the air moves.

Air compressors do focus the air in one stream though, so if you cut alot of thin stuff you might blow it away from position. Don´t buy one more compressor until you have tested with one.

And if you push in more air than you take out, you will get smell and smoke coming out from other cracks in the machine – always focus on more out than in.

Just wondering where you picked up the 12v to run the fans from, is there a spot on the PSU or the board?

I added a small 12v wall-plug to power 12v stuff. All my pumps are 12V so i already had it in the machine.

This seems like a silly question, but I want to make sure I’m understanding correctly. Did you cut through the sheet metal of your machine when installing the fans?

Not a silly question at all. Some K40 machines already have holes from the factory. There is 3-4-5 different machine cases on the K40.

If you do not have holes, you can use ahole punch, hole saw or dremel type cutter to cut holes.

A follow up idea, i mention this in the article too. I used my daughters hair dryer when i did a lot of testing with air flow from the front.

Air assist is not always needed, but you can try with a hair dryer on low setting and see what effect you get on the work you do with the laser.

You can also buy so called radial fans and just put them in the gap when lifting the lid a bit before deciding if you want or need to punch a hole in the machine.

Looking at the fans and how you installed them, isn’t there now a risk of a laser beam getting out of the encasing? Through the laser fans?

You probably never engrave on anything that can reflect the beam. If it does the beam is so out of focus anything it will hit is just heat. The beam loses it´s power 10-20cm (at this length the beam is 40-50cm wide and very dispersed) from the end mirror due to the scattering of the focus.

I tried firing the beam on a angled piece of copper (tube > mirror 1 > mirror 2 > mirror 3 > laser head lens > copper plate) and 5cm away i just felt heat similar to morning sun through a window. There is a risk of IR beams spreading in that but it´s also very unfocused and scattered, maybe if you stare in the fan outlet and engraving something very reflective you can get some kind of eye damage.

If you engrave a lot of reflective metals you can create some 90 degree fan guards to prevent this. It cannot cut through them no matter what power level you are at due to the unfocused beam.

The danger of the laser beam is anything happening to it between the laser tube and the focus lens – everything after that is pretty harmless once it starts to reflect and disperse.

Hi,

Don’t you have to worry about laser light reflections through the front fans? i.e. light could reflect and exit the enclosure it seems.

I’m wondering if some 3D printed 90 degrees elbow would not help there for the intakes. Not as good for airflow, but better to prevent light from escaping. What do you think?

Great site, thank you.

You have to engrave on something very reflective to cause that. Most material as acrylic or wood absorbs the beam.

Any scattering you get from it is just heat and you have to keep the hand very still for a long time until you notice it 🙂

Maybe for eye protection if you sit around the laser while its working at a desk or similar in the same height as the fan location, but even there it´s very unlikely you would get a bounce that can do any kind of harm.

The beam is unfocused and scattered like crazy, after 10-15cm it has lost almost all power.

Hi,

I am adding an air assist and got a 70l/min air pump but now I am wondering if it is better to instead add two 12v dc PC fans on the outside and one on the laser head with a 3d printed air assist nozzle. Which setup would be better?

Both, the flow of air from the PC fans would help keeping the material clean, and the beam path free of smoke. And the air assist helps with removing crap from the burn area.

I have two 80mm fans in the front of my machine, not always use them but when engraving with a lof of smoke they help.

In a older version of my laser head i had a 40mm fan on the laser head, with the open style lens holder and it helped alot.

Getting air moving through the machine + the laser head solves a lot of smoke and engraving/cutting quality problems.

Hi all, just looking at adding air assist but where’s the best place to tap into for the feed?

Never tap in to the PSU, add a old usb charger or phone carger instead to drive your fans. The stock PSU is already on the limit of what it can handle. Any problems ahead you can be sure whatever you added is not the cause of the problems.

Thank you that was very helpful.

Carol

Hi I have just brought a K40. Like you, most youtube videos also recommend adding an air pump but not sure whats the best size 20w 40w or higher I just don’t know. What would you recommend and whats the best way to attach it to the machine? Please bear in mind I am a 68-year-old woman and not very electronically minded, please keep your answer as simple as possible. Thank you Carol.

Haliea ACO 318, or something with 50-60L/min or more is a good pump. Just connect to a wall outlet and add the air hose to use as air assist. The air assist is aimed at the cut area of the laser to prevent smoke and debris in the laser beam, similar to car head lights – if its too much fog you wont see much. The air assist removes the smoke so the laser can “see” the material better, and engrave or cut it.

Hi, You say a pump with 60l/hour, did you happen to mean 60l/min?

Ahh, yes, per minute of course. I have edited the comment now! Thanks for noticing the error!

I am adding air assist to my K40. I think I will go for the Hailea pump, but what size hose do I need to buy to fit it? Is the coiled type easier to deal with?

Another question: should I go for a plastic printed nozzle that encloses the laser head (risk of melting?), or use a stainless tube on the side of the head that attaches with a plastic ring? Any thoughts gratefully received.

50L/min is good for regular engraving and cutting plastics, tile or stone. For wood i would go for 75-100L/min to get more flow as the wood is spewing out a lot of smoke when cut/engraved.

Hi HP, great info.

So how and where do you connect the pc fans to? I saw a schematic somewhere that the power supply only has a 5v and a 24v out?

I read a lot about people adding all sorts of stuff like laser pointers, fans, lights etc. but no one seems to talk about how they connect everything. I can solder, but I’m not well versed in the arts of volts, watts and ohms.

I always suggest adding a extra power source for fans and other stuff to the machine. If you get a problem further ahead, you will know for sure the stuff you added is not a reason for the problems. 12v and 2A can be found everywhere and very cheap, enough for some fans and lights. You might have a old wall plug somewhere from a screw driver charger or similar, just check the volts and amp output.

I agree with this. I’m good with electronics, can solder, know arduino, etc., but it’d be great to see some other folks secondary power supply setups for the other components they are running. I haven’t found any links for something like that. Maybe I need to document it and post on Instructables once I figure it all out!

I was going to comment on your “air assist” (that is why I ended up on the site), but no comment section.

I agree with your assessment. I actually have “that” air-assist, and it is much better than not having it. Without the air-assist, my lenses would require constant cleaning and wood would often catch fire. With this assist, I have had none of these problems (I don’t see any venturi effect as the lens itself blocks the path).

However, I was on a search because my newly purchased 25mm focal distance lens does work with this assist (the geometry of that system cannot bring the work piece close enough without interfering the x-axis). Having a fixed air-stream driving the smoke toward my exhaust path as your “brake line” assist makes a lot of sense (rather than blowing everywhere, then trying to exhaust it)…thanks

Yeah, any kind of air assist is better than none for sure 🙂

Looking at your picture, it would appear you have “something other than a stock K40″…your x-axis looks much larger than typical. To that point, I would not recommend anyone add any significant mass to K40 head (such as a fan)…the stepper motors/drivers cannot handle it and would start skipping steps quickly (especially while engraving at high speeds)

Correct, this is the newer design of the K40, often named K40D but its beefier both on the steppers and controller boards so no problem with the movements. I have the older style too but never tried adding anything to the head on that one though 🙂

The picture was mostly a example of air assist, the best solution is if the fans are in the case itself creating turbulence, eliminating the need for a big fan.

on the subject of motors, what is the current k40 motors rating? I`m looking to build a rotary and presume that ideally the motors should be the same so not to complicate the job.

Less than 1A power and 0.9 degree per step is what the original have. If you have upgraded the controller you can use bigger motors. The original board will burn sooner or later with 1,5 or 2A steppers.

Hi There,

Any ideas as to why all of a sudden our exhaust is blowing more smoke than usual when cutting timber / MDF. Never used to exhaust so much before but all of a sudden it seems to look like the side of house is on fire when we have the machine cutting. Having to cut at night as to not be so noticeable to neighbors.

Most probably it´s because outside temperatures drops now, colder air outside and you exhaust hot air will be more visible. Similar to breathing in cold air, or boiling water. The bigger temperature difference – the more it will be visible. And the humidity plays a big role too i beleive.

thanks for your reply. Our temps are actually increasing as we are in southern hemisphere. Think this would still be same issue.

I am considering putting 2 smaller computer fans, maybe 50-80mm in the front of my machine with holes cut for air intake, along with a 150cfm squirrel cage fan at the exit from my building, will this work well?

My thinking is if I seal the lid better and have a larger exhaust fan that having the two little ones sucking in fresh air to blow over work piece would move the smoke out fast with less escaping into my house.

Yes, anything that helps the exhaust will do better than no fans at all. Pushing air in will increase the pressure a bit so the exhaust has less negative pressure to make (to pull the air out).

The best ratio is somewhere about 1:0.9 where the intake is a bit less than output, to prevent smoke from being pushed out trough cracks in the case.

If you already have the squirrel fan, use it. If you going to buy one check out the inline fans instead, and keep it at the end of the hose, not back of the laser.

Thanks I already have the fan, it was off a Pellet stove that failed, so its free. I was going to mount it right at my window exhausting outside through a dryer vent type setup. It has flaps that close so rain doesn’t come in etc.