This post is intended for those who are considering purchasing a K40 laser cutter but need additional details beforehand.

To understand more about this machine family, see this page as well as all the others on the k40.

Recommended sellers

The links below lead to manufacturers or dealers with whom I have personal experience.

K40 – 3020, 40w laser machine

K40D – 3020, 40w laser machine

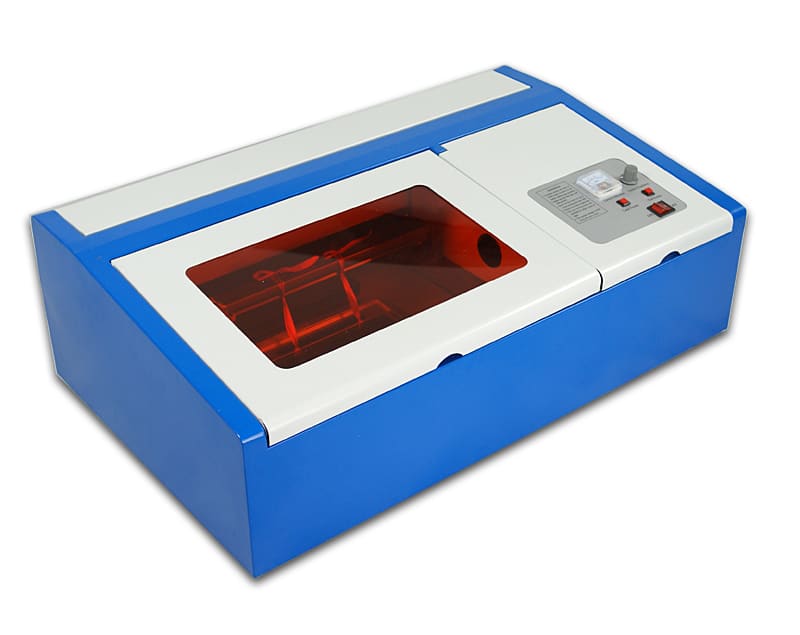

The K40 laser machine

Different types of cases

The K40 is frequently blue and white, but it also exists in other color combinations, including black-red, red-white, orange-black, and others. They are all the same; the gantry and controller should be examined more so than the color.

K40 analog version

K40 digital version

K40D newest machine type

Different types of gantrys

The K40 is frequently blue and white, but it also exists in other color combinations, including black-red, red-white, orange-black, and others. They are all the same; the gantry and controller should be examined more so than the color.

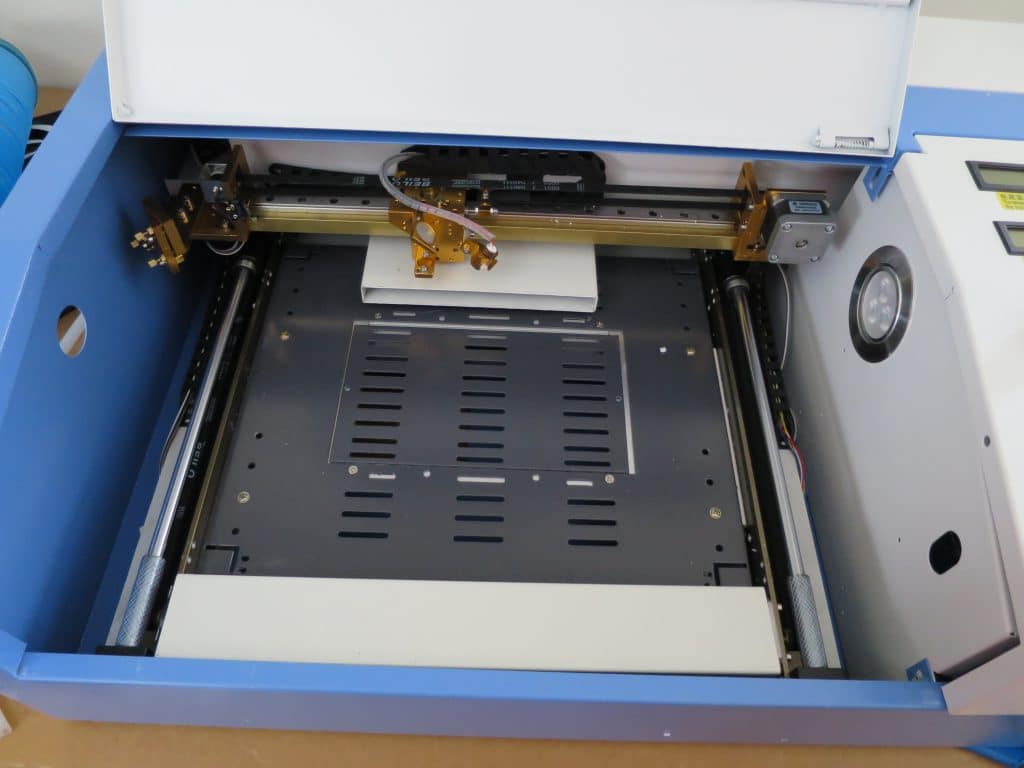

The regular gantry in the K40 is this type shown below. This is what you get in the most of the k40´s on the market.

Here is the K40D gantry, which is much better, less vibrations and overall better than the regular K40

Analog or digital

To put an end to debates about analog vs. digital, they are both exactly the same.

The digital panel displays a percentage that isn’t accurate; for example, 100% is not really 100%, its 150%!

To determine where your true limit is if you get a digital panel, you must to purchase a mA-meter to add to your system. (about 16–18 mA)

Here is a article how to install it.

Common problems and upgrades to expect

Security and electricity

The K40 is not a plug-and-play laser device, I repeat not. If you aren’t careful, the high voltages present here can and will kill you.

Read my post on how to set up a laser.

Gantry, optics, and machine case

The better you can seal the K40, which is not airtight, the less stench and smoke will leak outside the machine. Below are more articles on this.

The mirrors and lens that come with your computer are, at best, worthless, so be prepared to acquire an optics kit for it. Most people who use our mirror and lens sets see a 20–30% power improvement.

The gantry frequently has flaws, including improper alignment, poor end cuts that cause it to be out of square, and other issues. When it comes, give it a visual examination and put it up using the alignment guide.

Smoke and air assist.

If any sort of air assist is missing, you will definitely need it. Look at these articles about air assistance.

Check out this post about smoke assist to see how it can improve your exhaust.

The seller

Choose a few machines that interest you to start with (or check out my links below).

Read the comments, keep an eye on the vendors’ ratings and reviews, and try to remember that many people purchasing a K40 have never used a laser before.

Not all sellers, but the most of them, will fix any issues you encounter with the equipment.

If there are any issues, they are almost always related to delivery of the machine, which is why many sellers receive negative feedback.

Try to limit your business to vendors that have been in business for at least a year, and stay away from those who are selling rubber ding-dongs, laser machines, and lawn mowers all in the same place.

What to watch out for

As was previously mentioned, go with vendors who specialize in lasers and CNC equipment as they are knowledgeable about their products. Some vendors could struggle to assist you with your inquiries after the purchase and may only sell it to earn money.

Never send money directly to a PayPal account when paying; always use the website’s escrow service on Amazon, Ebay, or AliExpress.

PayPal wants you to send back significantly damaged equipment at your own cost, which is frequently greater than the cost of the equipment itself. Escrow services give you a lot more protection because the seller is required to rectify any issues you have with new equipment or replacement parts.

Avoid using Moshi controller with the machines; they are tagged with MoshiDraw, LDDraw, and similar names. Do not purchase this ancient, out-of-date controller because it has terrible functions.

Recommended sellers

The links below lead to manufacturers or dealers with whom I have personal experience. (Aliexpress)

K40 – 3020, 40w laser machine

K40D – 3020, 40w laser machine

What are your thoughts on the acrylic viewing panels these things come with? Do you think it’s sufficient to block out all the IR and UR radiation or should safety glasses or face shields be worn at all times when looking in the viewing panel or near it?

Yes, its enough for most usage. If acrylic were transparent to the beam, you would not be able to cut it. What may pass through is radiaton in the form of heat, but most of that is stopped too so if you see the window starts to bubble or deform – you are doing something strange 🙂

The reflected beam that might end up going towards the lid window is so scattered its only heat.

If you stand around and look at it cutting, wear a set of regular glasses, or protection glasses from the wood shop – they do the same work.

Only when using open machines without walls or when doing alignment i use laser protective goggles. But its nothing wrong with using it all the time either, you feel a bit safer and the safety level and precaution is up to you.

That’s good to hear, maybe I was just overly freaking out haha. Thanks for all your answers to my questions lately! Your site is such a valuable resource!

Hi HP, what do you think? is good to change lens after purchase of machine to get better performance for cutting?

Absolutely, go for a ZnSE or GE-lens. I would recommend getting one of each, some sellers on aliexpress/ebay/amazon have both of them. 12mm size and stay with the 50.8mm focal length.

The GE has some better beam shape and other things going on i can´t explain, but we could see a big difference in a machine measuring the lenses, aswell as cutting performance with a GE.

Hi HP,

great work. As I’m planning to get a K40D now (from your Link – Suzhou Industry City)…

Would you still recommend that model? Cost is 638€ right now (incl. shipping, NOT including TAX / Custom…)

I am capable of the electric rework I have to do. So ideally after three days of setting up, it should work 😛

Anything else you’d recommend?

Thanks

– Thorsten

Install the machine and learn how it works until you start with upgrades or improvements. Just make sure the electric stuff is fixed before turning it on 🙂

There might be other sellers of the K40D with lower price, look around and see if you find one, but the price is roughly that price for a K40D so it´s not bad.

Thanks for the info. Lots of good stuff. Can you recommend and of the ones on Amazon? I’m not seeing any K40D models there and none looks like the one you have posted here. Thanks.

It´s pretty much a hit and miss, most problems occurs in shipping and not problems with the seller. The K40D is often only made on order from china, never seen them around on ebay or amazon.

I am having trouble with my machine, it will fire when I test fire it but not much when running a program.

Check this article, and test the P-pin, its probably your problem: https://k40laser.se/diy-how-to/no-fire-troubleshooting/

HP I’m really struggling do you offer any services that could solve the allignment and focus issue. I live in the uk near Bradford?

I only offer remote help, as i´m located in Sweden. Have you followed my alignment guide, and the focus guide?

Hi HP great work helping out the community. Would you be able to assist me. I am trying to cut 3.2mm hardboard with a k40 do you think this is possible? Don’t think I’ve aligned the mirrors correctly yet. Maybe I might need a more powerful laser. Seem to only be cutting 1mm at the minute. Plus I have no air assist attached. Thanks for advice

Perfect alignment and focus is key, make sure you have 50.8mm minus half material thickness when cutting, if the lens is a 50.8 focal length. In you case you should have roughly 49mm between lens underside and material surface.