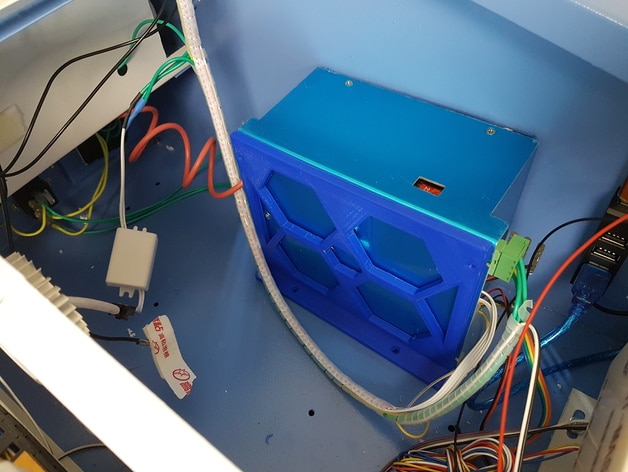

The most important thing with electronics is sufficient cooling. You don´t need to follow this article and flip your PSU, but look into adding one or more fans to take out the hot air from the smaller compartment.

Tilt your PSU´s – save your PSU from dying

Copyright © 2025 K40.se

Excellent site! Thank you for sharing you expertise. Back in my tv repair days we would identify a high voltage leak by a distinctive high pitch squeak. I notice similar sound in area of psu after a half minute of use and a 15% drop in current seems to support the leak theory but no visible arc or ozone. Any guidance on possible cause, locating and addressing? In the meantime, I plan to tilt my psu and reverse the fan to optimize breathing. hopefully cooling will help. Currently have a bench meter measuring current. Otherwise machine is still the digital version with no meter.

Check your coolant, take a 10L bucket or similar and put in your pump, run it and see if the sound is still there, or getting worse. You can use tap water for this test with some vinegar, dont leave the machine with the tap water after though.

The coolant – if very dirty (conductive) can cause strange things with the tube, some of the power goes to charge the water instead of hitting the catchode to keep up the gas regeneration process.

With your experience of repairing tv;s, i could suggest putting a mA-meter of any kind between the negative pin on the tube and the L- on the PSU and measure if you have any difference on output between your current coolant – and a bucket of tap water, this with any changes in sound between the noises might tell the story that it´s the coolant doing it.

If you see no change, i would think it´s the flyback on its way out. Also check the numbers on the rectifier located close to the internal fuse, it should be at least 4-6A (some has 8 or 10A, doesnt matter), google the numbers and look. Change it if its a 1 or 2A model.

Grounding is also a issue with these machine, you know with your experience that grounding is key, and the chinese sellers put plastic washers on the ground pin, double check yours that it´s clean and have proper ground connections and all cables and crimps look ok to the PSU.

You were right. The HV leak is inside the tube. I can see it arc sideways. Was using RO water but had not changed in a while. Cleaned and flushed and seeing much improvement. I’m now working through your cooling info. Thanks so much! PSU is tilted and permanent ammeter installed. 5 bad crimps found so thanks for that heads up.

Machine stopped working while setting up, was hesitating while jogging to position. Everything is dead no lights , ventilation , or digital read outs. Looked at fuse ,appears to be good, no visible burns on board . Machine has a jg-40w power supply ,rectifier bridge is a GBU 610. What should I look at next?

Check the fuse in the back of the machine too, and on the board inside the PSU. Its located in the connector in the back. GBU610 is enough and should not burn.

Thanks for the detailed website! There is a lot of valuable information here. I have a question about tilting the power supply 90Deg.

You said “Tilt the PSU 90 degrees, so the fan in the PSU grabs air from the ambient temp in your room, instead of breathing the heated air inside the machine.”

I have slots on the side of the machine where ambient temp air could be pulled into the housing that contains the PSU, but the fan on my power supply blows out away from the PSU not blowing INTO the PSU. Is this still correct? Because It would still grab warm air from inside the compartment and exhaust it out the slots on the side of my machine.

Or should I flip the fan around so it would draw air in from the slots, and blow it across the PCB of the Power Supply?

Flip the fan, i have seen others mention this too. Seems like the fan is mounted either way depending on which seller it is 🙂