This is a short warning with information how to solve the issue.

More and more machines are delivered with deadly configuration on the grounding of the electronics.

In China, the electric standard is not well built and many houses still do not have ground solutions in their house. So the machines are built by their standard, when we in EU or US or other parts of the world often have a good ground setup already in our homes since many years.

If you have a 3-prong outlet from your wall, you do not need (and should not) ground it from the ground bolt.[bsf-info-box icon=”Defaults-exclamation-triangle warning” icon_size=”32″ icon_color=”#dd3333″ icon_animation=”swing” title=”Important information” pos=”square_box” box_border_style=”dashed” box_border_width=”2″ box_border_color=”#dd3333″]This guide expect that your ground wiring where you have the laser is up to code.

If you are uncertain your ground are safe in your house – consult a electrician.

The problem

The internal electronic parts are grounded to the ground bolt in the rear of the machine, so is the ground line in the cable you plug to your wall outlet.

But, the bolt itself are often isolated from the machine case which is a big problem, first off for your safety, second for the current regulations and laws about machines with high voltage.

In China they do this because the grounding is external and not inside the cable from their wall outlets. But for us who think the case ground is properly done – it can and will kill you!

How to identify and fix this problem

Start with removing the ground bolt from your machine.

Use abrasive paper or a knife to scrape away some paint around the hole for the ground bolt. Both inside and outside.

Remove ALL plastic/nylon washers from the ground bolt, only use metal washers.

Some bolts has a plastic spacer, you might need this.

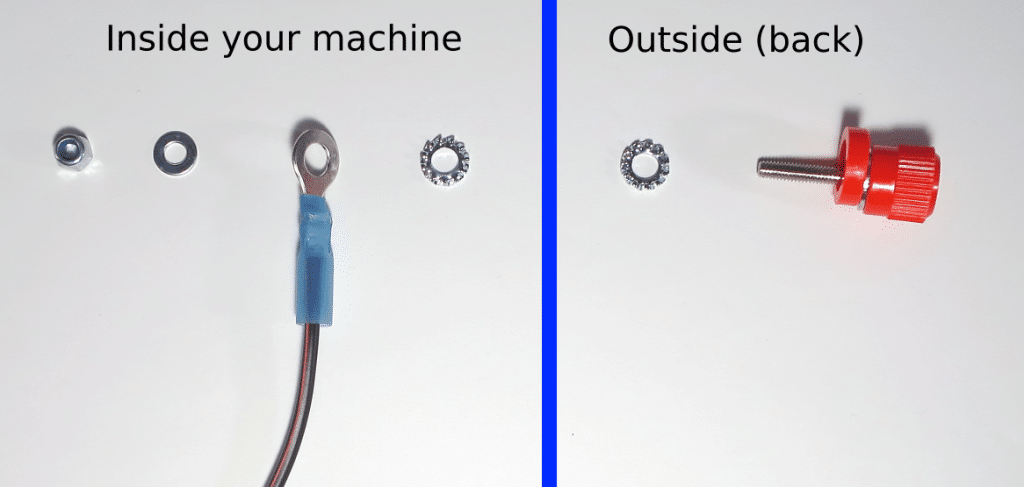

Here is a layout that will give you a good ground connection.

Now mount the bolt in your machine again.

The lock nut will ensure your bolt never comes off again. You can also use loctite or two nuts.

Here is a picture how a good ground bolt is fastened to your machine.

I use two toothed/serrated washers closest to the metal.

I’m not an EE, so research this/form your own opinion. I’m under the impression that using a ground rod with a properly grounded outlet could cause a ground loop.

Another thing that I’m curious about, my K40 came with the ground bolt isolated from the chassis with plastic washers, but even with the ground lug and IEC inlet disconnected (floating) from the chassis, the ground lug still has continuity with the chassis. This illustrates fairly clearly that there is another chassis ground point. The thing that is concerning (from what I understand) for US safety standards is that the IEC earth is supposed to have its own independent chassis connection, serving no other purpose. However, even if you connect the ground point directly to the chassis, that’s (at quick glance) also appears to be grounding the PT. It seems like there should be 2 different chassis connections for these two wires. I’m not 100% sure that’s correct, so if somebody knows for sure, please chime in.

Correct, some machines has a FC ground through the metal case of the power supply. But alot of them has isolating washers there too (or a plastic wrap preventing good ground). So in my guide i just made it simpler to fix the ground pin. And as you say, not use ground rod and groundet outlets at the same time.

Thanks for these guides HP. I did some reading through the site before my laser arrived, I’m still in the process of giving it a once over before using it, but the info here has given me a huge head start.

I’ve been googling for a while now to fix my issue.

I live in an appartment built in the 60’s meaning there is no ground.

In the kitchen there are plugs with a 3rd (ground) pin, but measuring with a multimeter I can tell it’s not connected with anything. (There is a ground cable connected to it, but I guess it’s not truelly grounded).

If i’m correct I should indeed connect the grounded bolt to ground…

It’s just that I can’t really hammer a metal pin in the ground since I live in an appartment.

The only option would be to make sure the ground is actually grounded in the appartment?

I noticed in a video that someone (with a grounded plug) used the plug + connected the ground bolt with a radiator.

Don’t really know what to think of that since I don’t wan’t to electrocute my neighbours…

Yes, you need a ground. Water pipes might work if they are actually grounded, in Sweden 99% are but not sure about other countries, they might be grounded to a heating tank and grounding the laser to that might cause issues with the heater.

Offer a bag of cookies or similar to a local electrician who can help you check proper ground.

The kitchen should have ground, it´s a better bet than water pipes.

The machine will work without, but it´s not safe and it can cause strange things with the laser output.

There’s a ground wire connected to the kitchen plugs, but measuring it with a multimeter proves it’s not connected with anything. I’ll be in touch with the appartment syndic about getting ground…

Pretty funky since the electrician that came a few years back said that everything is grounded…

Thanks for the quick reply!

This might be obvious to most, but just in case: my K40 was supplied with a two pin plug, so NOT including a connection to my wall socket’s ground. Connecting the machine’s case with ground by scraping the paint by the ground bolt in the back etc. is very important for safety, but will only work if the machine is plugged into the wall socket with a power cable that includes a ground connection!

Good point, i also heard reports of users getting the 3-prong cable – but the ground is not connected to both ends of the cable.

This s quite a nice forum.

my laser engraver JK-1390, stopped burning while running

the gantry is okey. But the laser power is off or simply a little pulse at the corner. BUR have realised its not earthed.

how can I solve this problem?

Start with following the guide above, you need to make sure you have it grounded.

After that you can start by checking out the “no fire troubleshooting” guide to find out more what your machine can have trouble with.

If the beam is weak or just pulses for a half second, your tube or PSU might be out. But focus on the grounding first, then look in to the problems. It might be the cause of killing the tube for you.

People are getting confused because it reads like if you live in the US or UK you don’t need to use the rear ground bolt. While this is true, the bolt still MUST be in good contact with metal case. Look at the inside near the plug input. The ground from the 3 prong connection swings over to the bolt. So Even if you live in the US and do not plan on running a wire from the rear of machine to a ground, it is still being used, the 3rd prong connects to it.

This is so helpful. Just got one of these and was worried about the earth ground in manual. This is much better solution. Definitely want to be safe using this thing. My house was built in 2003 in USA so it has all grounded outlets. I was wondering why it would need additionally grounding. Now I have to find a way to tell my husband thAt I bought this machine…

Show him this website and he´ll probably be okay with it as a safe machine to use, and probably join you with the adventures making stuff with it 😉

Super – thank for this Info

I can give the electrical safety theory behind this. Here’s the danger scenario that is prevented by this upgrade:

1) The machine gets some internal damage, such that a high-voltage wire starts touching its metal case (for example, the laser tube breaks and the high-voltage line of the laser supply touches the case). The case is now just sitting there with a high voltage relative to the earth, waiting for you to touch it.

2) You’re standing on the earth, so your feet are somewhat connected to the earth.

3) You touch the case. Now there’s high voltage between your hand and your feet, causing a current to flow through your heart. The amount of current flowing from the machine case to the earth through your heart depends on how well your feet are connected to the earth, but it might be enough to kill you.

The standard solution (in well-made equipment) is to prevent part 1 of the scenario. The manufacturer connects the machine’s metal case to the earth via your house’s ground wire (the center prong on the three-prong plug). Now, if the damage in part 1) happens, current will immediately flow to earth through the ground wire. Thus, an electrical fault CAN’T charge the case to a high voltage relative to ground, because the case is connected directly to ground.

In other words, the ground wire forces the case to the same electrical potential as the earth (and you) so that touching the case won’t shock you. (Another way to look at it: the grounding wire provides a much lower-resistance path to the earth than your body does, so 99.999% of the current flows through the grounding wire and not through you.) Your clothes dryer, power tools, etc all have grounded cases for this reason.

On my K40 I confirmed that the red external ground plug is connected to the house wiring’s ground, but the metal case is NOT. So, the point of this upgrade is to properly connect the metal case to earth ground.

From my research, I found that the reason for grounding is that if a high voltage wire were to come in contact with the case, and it was grounded correctly, there would be a surge of current from the live wire, to the ground, which would trip the breaker.

I see sense in your theory, but I’m pretty sure that the breaker gets blown once the live touches the ground (and short circuits). One (bad) trick I was shown by my previous employer was, if you’re installing a new outlet and don’t want to go and find what breaker it’s on, touch the live to the ground and it will trip the breaker, therefore making it “safe” to switch out the outlet. Bad advice yes, but shows the live to ground tripping the breaker does in fact happen.

I suppose if there wasn’t good contact with the live wire and the case, it may not trip the breaker. But if there was life-threatening contact, the breaker should trip..

Hi

I have had a k40 for a few months but only just set it up. It does not work. I followed your grounding instructions with the nasty blue wire supplied but still no luck. The gantry works well and there is power to the sight dot which is not good. When I test fire there is a clicking sound and I think there is some blackening at the business end but no laser. Frustrating. I have a feeling there might be water in the wrong places too but not crack and no water leak. Where should I not see water? Thanks in advance.

Try put a jumper between P and GND, or P+ and P- depending on PSU. This will disable the safety feature, some machines has a flow sensor on this, some is just bridged.

Didn’t quite understand where the grounding cable must go when inside the machine!

Can you please explain where it will go?

Ground wire goes to the ground bolt, and the bolt has contact with the metal case.

But if I read this right, you do NOT need to run a wire to an external earth ground if you have a three-prong outlet, like we have here in the US, correct? I have one of the larger Redsail x700 clones and my electrician installed an exterior earth ground when I had him wire a dedicated 20a circuit for the unit. There is a stiff copper wire that enters the basement through the exterior wall and I run a wire from the ground terminal on the back of the machine to the connector on the external earth ground. Is this overkill???

Also, I’m guessing my case ground post is not making good contact. There was paint on both sides and the bolt had plastic insulators on both sides of the case. That tells me the only contact between the case and ground bolt was the edge of the hole drilled into the case.

Would appreciate your feedback!

If you have a ground rod, use it. If it´s overkill or not depends on your buildings ground status.

Remove all plastic shit and remove paint and ground the machine case properly and it works great, no matter if you use the ground rod or a good wall outlet ground.

Yes he did it proper. Any machine capable of producing a voltage above 600 needs to have a separate earth ground of a number 8 or 6 depending on local code. UL is #8. Ive wired machines well over a million dollars and always. Ground externally…On my machine i have also bonded each of the 3 covers to the main cabinet also. Having installed and service all types of industrial machines for close to 35 years now. Each removable cover needs a #10 ground!!! Never relay on a 18awg ground wire inside a Chinese made cord, that is actually closer to 20awg and copper clad capable of 5 amps max. Taking that into consideration its your life. Also i have my water reservoir grounded. Having taken so many grounding courses. Its a must.

Thanks for sharing the grounding information.

À lot of the K40 machines i’ve seen have the CE mark on it meaning that it

Should have been tested accordingly to the CE safety standard.

The chinese give à damn About these safety standards, just look at the cheap

LEDs for 220volts, a lot of them can be simply touched on the 220v parts.

À big compliment About Your website, very helpfull, thanks.

Fake CE markings, some call it “chinese export” and not the real Conformité Européenne

I have just installed a new K40 laser in my shed. I intend to do the upgrade once i am confident with using the laser but for now i’ll use it as it is. I have everything connected but noticed (by accident) that there is a slight electric shock coming from the casing. I live in the UK and have a 3 prong plug for the power supply… Can you advise what I need to do? I am not knowledgeable what-so-ever with electric so please use easy terminology. Thanks

Read the electric warning article i wrote a while back, in the FAQ menu. The problem is often the ground bolt in the back beeing isolated from the casing, this is where the ground from the wall outlet should have 100% contact with the metal. Take a look in the article and follow the steps and it will probaly solve your issue. If not, you have bad grounding to your shed.

Is this meant for US owners also? House is grounded. Do I need to perform these steps but not use the ground from the post on the machine? I see a loop back to the grounding.

For everyone. You do not need a cable on the outside of the machine if you have 3 prongs from your wall outlet. Just make sure the metal is clean so the ground bolt has proper connection. This is where the ground from the wall is bolted down, it has to be 100% good contact.