K40 laser wiring diagram and pinout

Most problems with the K40 laser cutter involves the power supply in one way or another.

Here is the facts about the laser power supply installed in most K40 machines with complete pinout and wiring for the different types.

Introduction

The K40 is a product made with parts to make a small and cheap laser machine.

It is not developed or manufactured like this – it´s just the cheapest parts and solutions put in to a metal box.

Now when we talk about the Laser Power Supply it is actually not made to be used as it is in the K40 laser machine at all.

The power supply

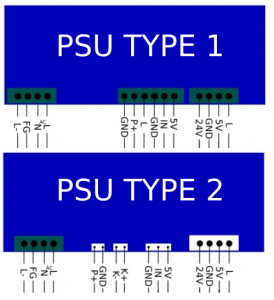

There is 5-6 types of MYJG-psu´s in the K40 machines delivered, they are mostly two types with some differences on the pin layout and connector type.

In this article i will show two types who covers 95% of all types – if you have another type it is probably very close to one of the two types shown here.

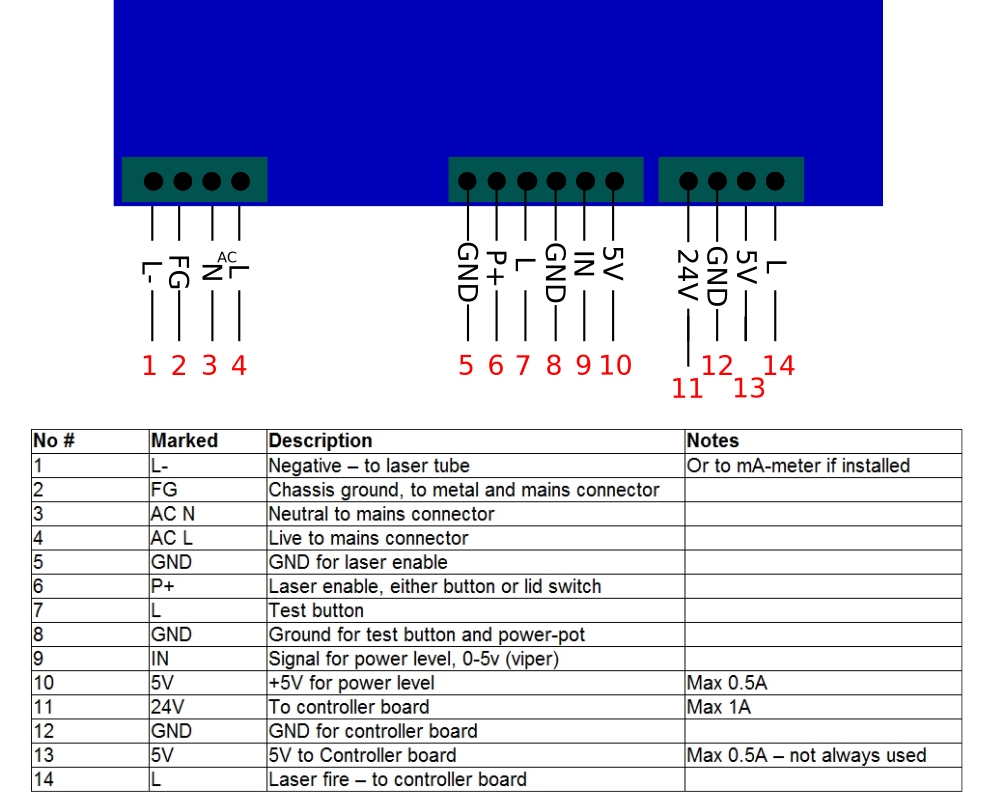

Pinout / wiring

Please note – the pins are marked as they are written on the PCB. The P+ and P- are printed wrong on the Type2 PSU board – it does not matter though but they are actually the other way around.

The connectors on PSU Type 2 are JST XH 2.54mm.

Pinout table

L- Laser tube ground

FG – Case ground

AC-N – AC neutral

AC-L – AC live

GND – Ground

P+ – Together with a GND – connect flow meter, lid switch or other protection here.

IN – Signal in for power setting, 0-5 volt

5V – 5V output for use with power potentiometer or feeding the optical end stops

24V – Output for the controller board power

L – Laser fire pin.

Common problems

The most common issue with the PSU´s has been the flyback transformer and/or the rectifier which has been of very low quality burning them and with arcing or no fire as a result.

You can prevent this a lot by making sure your machine is properly grounded (grounding your k40 article) – and make sure the rectifier are of a 4A model or more. Read the numbers on the rectifier to see what type you have installed. It needs soldering to be swapped.

Other problems involves no-fire issues – check out this article how to find the problem

Picture of the flyback transformer

Upgrades you should do

Cooling

The priority upgrade you should do is adding more cooling to the power supply compartment. Make sure you push air in to prevent sucking smoke out of the machine. Add a 50-120mm fan and push in some air, or tilt your PSU to let it breathe air from the outside.

This prevents it from heating up the air inside the machine and trying to cool itself with the already heated air.

24V external power supply

The MYJG-40 has never been made to run the stepper motors from the internal 24V line, the internal 24V is for running your controller board and nothing else. With the K40 setup of controller you cannot have a external PSU for the motors so you need to add both the controller and motors to a new 24V PSU.

24V with 4A is enough for our machines. Read this article for installation instructions.

Replacement Flyback transformer

Before you buy a flyback – make sure yours are identical with the one you order.

Flyback transformer (external link to Aliexpress)

Replacement PSU´s

The standard 40W PSU (external link to Aliexpress)

Upgraded PSU´s

A PSU i personally run i every machine is the HY-T50, very stable and nice PSU without any problems. I have bought and installed at least 100 of them and what i know so far only three has been sent back for warranty claims.

HY-T50 on Aliexpress

[bsf-info-box icon=”Defaults-heart” icon_size=”32″ icon_color=”#dd3333″ pos=”left”]Some links in this article are affiliate links – it helps with keeping this website alive and my fridge filled with Pepsi for my long hours writing all articles 🙂

Hi K40.SE

Could you please just give me a quick answer on the pin out on Type 1 PSU.

I am looking at the middle plug at Pin No 3 its shown in the PSU Type 1 graphic above as L . From the explanation directly below the pinouts I have to admit some confusion as to what this means, is the L for AC Live, or DC Live ( if so what DC Voltage please?) or is it something else please as I cant see an explanation for it between P+ and Ground in your table under the graphics.

Would you mind just letting me know please. Many thanks and it is a great resource your site.

Many thanks.

Neil Barcelona Spain.

AC L and N are neutral and live for AC input, 120 or 230 volts depending on the type of PSU and what the psu is set to. (some has a switch between 120 and 230).

FG is case ground and L- is negative from laser tube.

Thanks for that however it’s left me even more confused now, Its probably me I was involved in a nasty car crash and obtained a broken arm earlier in the week. Still getting over it.

I am talking about Plug no 2 in the PSU type 1, it’s the middle plug. Pin 3 from the left on your graphic above.

It just has a L against it in the graphic above . I just don’t understand however what that L is for, live AC or Live DC?

Please advise as I am sorry that I simply dont understand your original reply. I am just looking for an explanation to Pin 3 not any other pins. I’m in Spain so the PSU is 230 v

From tracing it back to its source this pin seems to operate one side of the laser test switch, I am building a new control panel and I just want to know what voltage goes across this switch so i dont end up buying the wrong type of push button switch for it. That’s all

Many thanks.

Only the first N/L are AC, the rest are DC or ground pins.

All other L-pins are pins for firing the laser. This is connected to a controller board output. This is not AC.

This image is a bit better:

Got given a K40 laser, which I was told had died. Managed to get it to work, but output would not get above 3ma on the inbuilt meter, and power supply whistles when laser fires. Tube was arcing inside the glass, and after reading lots of stuff on the net, replaced the tube. New tube installed no problem. Output has not changed. So I presume the next step is a new power supply ?. I did check the potentiometer, and it seems to be working correctly. Zero volts when turned down, and Max 5 volts turned up.

No arcing to be seen anywhere.

Anything else to check before ordering a new PS ??

Yes this is typical for a dead flyback transformer. You can either buy only that one for $15-20 or a new psu, i would suggest HY-T50 or MyJG-50 if you buy a whole PSU.

Hello, I read through this article and through your comments here. One comment had a good reference for swapping for a T50 and I was hoping you could confirm that I plan on wiring this correctly. The included image is how I think the wires translate on the different labels. Sorry if it is a bit messy. The options being on different sides did not help but I tried to make it clear. Thank you for your time.

This picture is from type2 PSU and with a digital panel, its a bit different.

Do you have digital panel on your machine? and this type of PSU or the one with green connectors?

I can make a layout for you.

Hello! I wanted to say thank you for all your help over the last few weeks. It has taken me some time but with your guidance and troubleshooting I have an operational laser that is running quite reliably now. I have not swapped out the PSU as I was still hoping to see a diagram one day, but I am confident enough to install the 24v no problem. Very happy now with the results and currently working on keeping my office from smelling like the burned wood (sealing the machine and getting a better extractor).

Thank you again, your site has been an absolute blessing!

Thank you!

A new article coming shortly with pictures and diagram for connecting 24v and the other type of PSU´s to the k40´s.

I mentioned before that after installing my new PSU my output maxed out around 12 MA. I installed a new 50 watt PSU and oddly my MA has not changed. I use my k40 regularly. The laser output is steady and for all intense and purposes has been working great, minus the power drop. Anybody have any ideas?

Thanks

If you get stuck and tested with two PSU´s, the tube cannot energize enough. The reading you get on the mA-meter is whats left after energizing the tube. The real output is 1-2 A and the tube has a efficiency of roughly 10%, the rest is heat.

The test button on the PSU bypasses all power settings so it should give you 18-21mA, sometimes a bit more.

Make sure the mA-meter is properly installed, and the cables not damaged or bad crimps. You can also test it with a multimeter, just keep your hands off when test-firing to make sure the mA-meter is working properly.

If everything checks out, it seems like a bad tube, or a tube on its way out.

Good day!

I went ahead and purchased a new tube

https://www.amazon.com/gp/product/B00BKWOS1E/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&th=1

I am having the same exact results with the output going no higher than 12/13 mA.

Thoughts?

Thanks!

You did change the PSU right? have you tested the mA-meter? removing it and check with a multimeter instead. Just dont hold the wires when doing that, your EKG will change (or stop) 😉

Thanks for the safety advice:) I have my multimeter hooked up to my analogue MA dial on the k40 and am actually only reading 9ma on my multimeter.

Yes, replaced my PSU with a 50 watt actually. All my wiring entering the PSU is snug as I have checked that multiple times. Is it possible I have a wire connected to a wrong port in my PSU?

Sounds really strange, almost like the PSU isn´t 100% good.

If the ground is bad it might give you similar effect, but it would start to arc pretty soon.

No wrong wires can cause this. Bad connection to the tube positive side, or the ground from the tube can cause it. Or just a bad PSU, but that is really strange too if you bought a T50/MyJG50

Is the PSU set to your live wire voltage? i was thinking if you have 120V in the wall outlet, and maybe PSU is set to 250? But dont move it if you have 250 wall power and its on 250 – it will blow up.

Holy crap! I feel like a moron! I have never received a PSU that wasn’t pre set to my native power. Im in the states. It was set to 220!!!!!!!! Thank you very much for making think of the most simple probability here. I am outputting at proper power.

Thanks again !

Good day!

Am I right to understand that a 50 watt psu would be fine for the k40 ? I purchased a replacement 40 watt PSU and my laser output would not get above 12 ma.

Let me know your thoughts.

Thank your time and expertise.

🙂

Yes, 50, 80 or 100w psu´s will work on 40w tubes. You just have to watch the output. Similar to putting a bigger engine in a small car, they might not like the full power of the bigger engine 🙂

If you are stuck at 12mA, do some test-cutting and see if the tube “sputter”, if you get uneven cuts or jagged edges.

My first guess would be a laser tube on its way out, but it can also be a bad PSU delivered to you. But if the test cutting you do shows this, i would say the tube. You can watch the purple plasma in the tube too, if that dances around alot its probably the tube. Try different power outputs, the higher the power and less gas in the tube, it will dance more.

Thanks so much for the response. Yeah it’s weird, the original psu gave me a solid 20ma when I wanted to risk it. This new 40watt psu isn’t outputting the same even though the construction/manufacturing is theoretically better than the original. It’s confusing. I’ll check out the tube as you recommended.

It’s really awesome that you set this site up. Its a valuable service. Much appreciated:)

Hello,

can you please tell me the difference between the MYJG-50W PSU and the HY-T50 PSU?

I asked cloudray themselves, but the answer was “there is no difference, you can use them both” Hahaha….

I am from Germany and the reason why i am asking is, that cloudray has the MYJG-50 in a european Stock, so delivery is fast and there are no customs costs. But if the HY-T50 is the better choice i will oder that via your Link in China by Aliexpress.

Best regards

Andreas

Not much difference, the T50 was made earlier, the MYJG-50 is made now the latest years and they are both great upgrades! Take the one closest to you 🙂

I use both types myself.

OK, thank you! 🙂

Hi, I have a MYJG-50W PSU that I would like to use to replace the stock K40 PSU with, are you able to tell me which wire goes where, there are fewer outlets than stock, and it’s not obvious, to me, where the tube negative comes from.

Some cables has to be two or more in one connection, example is G/GND and TL.

See here. (first is where the cable was on the old PSU, second is what its marked on the T50)

L- | blue in the back

FG To FG and Case ground bolt, double check it has connection.

N & L the two AC ports

P+ | WP

IN | IN

5V | 5V

24V+ red cable on the 24v external psu

24V- black cable on the 24v external psu

5V | 5V on the T50

L | TL

Thank you, that makes everything clearer, I was forgetting about the external 24v board supply, I have a Cohesion board, so that is sorted. Now to wire it in, thanks again.

I wanted to replace my k40 power supply (PSU type 1) with the cloudray 50w hy-t50 but I saw the pinout are completely different. Could you tell me how to make theconnections?

Check out my reply on this comment with all details you need.

https://k40.se/k40-laser-upgrades/psu-upgrade/#comment-39981

Help me I am lost! I have switched from std psu 40 watt to hyt50+ 24v psu and something is going wrong. It fires but step motors moves from xy(0,0) to opposite angle. I need wiring diagram to switch from old to new psu!

It seems like your end-stops are acting up. You need to make sure they still get a 5V feed or swap them out for mechanical switches.

If it moves very slow to the right when you turn it on, it´s the end-stops, not the PSU.

Double check the flat cable from the controller and the cables located around the end-stops and stepper motors to make sure it´s not a cable issue.

Solved! it was a bad grounding with the 24v psu! Thanks for your support 🙂

Do you know what the connector is for Type Two psu p+/g connection? I think I have identified it as jst xh 2.54mm 2pin connectors, but would like to confirm.

Thank you!

Yes, JST XH 2.54mm connectors is what i use on my PSU with this type of connectors.

Good thing you asked, i have added it to the article now too.

how do u how do you connect the controller to the hyt50

Similar as the stock power supply.

L from the controller connects to TL on the T50.

You need a external 24V psu for the controller though, not built in to the T50.

hi, it is not clear where is the diagram to connect an external power supply for the K40

Tks

We had to re-write it, hope to have it up tomorrow.

thank you very much for your availability

The article is now back online again.

Hi,

I bought a laser model K40 through ebay and since it arrived a few weeks ago when I performed the function tests I could verify that it is not cutting. I tried to solve the problem in several ways like in the youtube videos that I found related to the problems, but without success. I read checked the alignment of the light path, the alignment of the lenses but still does not cut. I recently bought the Upgraded – Adjustable laser head kit with air assist – 12mm from you and I am waiting for the delivery of the items to have more resources for a more precise adjustment of the laser focus, but I am afraid that the problem is something more serious related, for example with the PSU and subsequently with the laser power.

I would like to ask for help for your knowledge and experience with the K40 model and help me to solve the problem with my machine.

Regards,

Rubio Drager

Make sure you are in 100% perfect focus. If you have the material too high or low you cannot cut it properly.

See this article: https://k40laser.se/diy-how-to/setting-the-proper-focus-in-your-k40/

If you still have problems i would check every mirror for problems, put a piece of paper in front of mirror 1, make sure you hit aprox. center. Then test mirror 2 and 3, and lastly the lens – so you are sure you hit inside the mirror and lens. It´s easy to hit a edge on the mirror or lens and this will cause very low power in the end.

But start with the focus so you are correct in height.