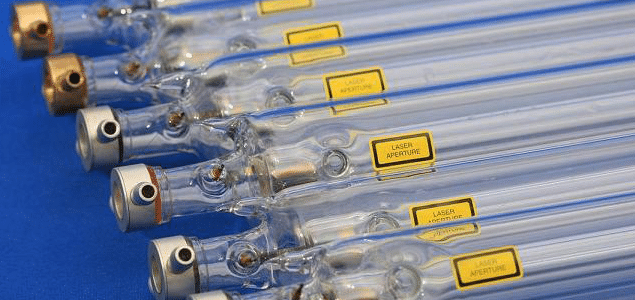

Most of us experience this sooner or later, but if you experience it really close to where your machine was delivered, here is the two top reasons why your laser tube died.

1: Overpowering the tube

While the tubes are called 40w, they cannot really handle 40w and has a effective output of about 30-35 watts depending on tube quality.

This mostly happens on the digital versions of the K40, where the milliamp. output isnt visible, only a percentage of the power.

Theese machines cannot handle 100%, they cannot handle 90%, you will overpower your tube at 90%, thus lowering the life span drastically.

If you have a digital version, i suggest installing a 30mA amp meter.

Keep your tube below 18mA at all times to be safe. You can go up to 20-25 but the gain is very little and you are strangling your tube for every second doing it.

2: Overheating the tube

This is pretty common, not having a clue about the water temperature in your tank and just running the machine.

The laser tube works the best at 15-20c water temp, anything above will degrade your tube.

If you run at 23c your tube will not die tomorrow, but you may lower the expected life time by a couple of weeks or month. So for some its ok to run at 23c as they know they need a tube change later on.

There is also a link between using wrong coolant to unexpected tube malfunctions.

Read more about that in the watercooling article.

But if you want to use your tube the most, keep temperature around 20c.

Whats happening when the temperature is too high is the regenerative gases has harder to regenerate inside the tube wich lowers the power output with time.

There is a deeper scientific explanation, but i keep it simple and understandable for now 😉

Quick info: Never go beyond 18mA and keep water att 20c or lower 🙂

Hi,

whow do i connect the electrodes with a cable?

Regards,

TB

Sorry for slow reply, but you do this with RTV silicone. Twist it a few times around the post, add a piece of hose, 5-6cm over it and fill the hose to cover the connection with silicone.

Does it only harm the laser-tube if it heats up during use, or is it also if it is in a warm room when it is turned off? I keep it mine in an attic where it sometimes goes up to 30 degrees Celsius (when turned off).

No, this is okay. The heat inside the tube when running is extremely high so 30-40-50c inside your house just sitting around does not harm it.

Try to keep it away from direct sunlight to prevent quick temp changes, that might crack the tube.

Thank you!

Hello helpers i have a problem with my k40 when engraving a rubber stamp of 40x60mm. the result is where there is text there is a nice deep cut and where there is no text there is a very shallow engraving it will be unusable i dont know what would be wrong your help might help me out i want to make a living with it until i upgrade to a bigger machine

Test with other material, plastic or wood if its the same, if you get identical result its the machine, if not its the material reaction.

Yes on Perspex/Acrylic its nice, Cuts neatly, engraves text neatly and sounds sharply when runningmaybe it is because i tested on the back of an old stamp rubber

Yeah, this is a material problem, not a machine issue 🙂

Order some fresh tests from a supplier of stamp material and you are probably getting better results.

Its always a bit harder to engrave on rubber, a lot of trial and error until you hit a sweet spot. And rubber is very different too so the settings you have now might not work at all if you buy from another supplier in the future and you have to start over with finding the best settings again.

Thanks i now understand thank uu

one day i tried 40% power and 10mm/s x 2passes for a rubber stamp and it came out usable i can give it a client but using such power can it ne that my tube might be getting weak and when temperature rises up the engraving effect quality changes it was a used machine when i bought it

Your 40% can be anything, you need to measure in milliamps (mA) to compare to a normal output from a standard K40 machine.

40% on your machine might be 65% on mine, they are all different and some are pushing 120% power when the meter says 80% 🙂

So install a mA-meter to make sure you keep it below safe limits, in my opinion that limit is 16-18mA with good cool water.

Please excuse my rough translation. I just bought a used K40 laser that does not cut properly. Here is my problem and its chronology (see photo): #1 the cut works when the laser is switched on for 2mm #2 loss of power then gradual increase for +/-4 seconds #3 stable power but comparable to a 25W machine # 4 in the job, the problem comes back more or less depending on the interruption time between 2 curves to be cut. To ensure the cutting of 3mm plywood I have to advance at 4mm/s and 14mA (potentiometer 70%). I am forcing the machine for nothing. I followed the different recommendations (alignment of mirrors, clean lens, ground, additional 24V power supply) and now I see 2 possible problems: dead laser and/or dead power supply. The shape of the laser beam is not circular (see photo). However, the problem of increasing power also resembles a problem of power supply. In doubt I could change the 2 but I do not have the means at the moment. Thank you for your opinions.

If you have a water flow meter connected to P+ and GND, remove it at put a small cable between P+ and GND and test again.

These meters sometimes react on low flow and the machine will turn the laser on-off-on-off very quickly and you can get this effect.

Thank you for your reply.

The machine does not have a flow meter. Apart from the additional 24V power supply, all the wiring and electronics are original. P+ and GRD include only the pink cables of the “Laser Switch”. The pump works continuously even when the laser is at rest (tested at 1.66L/min). I cleaned the tube with white vinegar (24h), I changed the demineralized water, removed all the air bubbles, I tried Whisperer and MeerK40t but the results are identical. The rectifier bridge seems sufficient (GBU 610 – 6A 1000V) and I don’t see any arcing on the tube or on the power supply. Here is the photo of the shape of the laser beam. I find the shape of the impact strange, it’s not circular. In the tube the path of the beam becomes more stable and linear after 4 seconds. Which is consistent with the ramp-up time and that’s the problem. To partially overcome the problem, I cut out a 5×5 square at the start of the program to “heat” the tube. I have recently become the third owner of the machine but have never seen it cut properly.

There isn’t much left though! A tube, a power supply, a potentiometer, an ammeter, a few cables and switches… what’s wrong?

Ah, this is due to the laser tube when it forms the beam. When the beam is created it goes through different stages and if one stage isnt stable it will fluctuate between different stages, like donut-shape to dot and similar. (google for tem01 to see examples)

If you get 6mA or more output you can be pretty sure this is a laser tube issue.

You can take a mirror and look inside the laser tube, there is a mirror on the output end, sometimes this gets very dirty or cracks and can cause issues like this too.

If its in good quality, i would bet on the laser tube.

My mA meter is all set up – I just had the digital % power meter – thank you for the guide! Regarding temperature, most of the comments talk of high temperature, but does low temperature have an effect? You mention ideal temp of 15-18’C but my laser (recently upscaled the tube and PSU to 50W) is in a garden building and currently the water temp is about 6-8’C. Does anyone have any experience or comments about low temp?

Lower temps are better, but you dont gain any function below 12-15c. The regeneration of gasses is working better on lower temps than on high.

6-8c is no problems.

Thats great – thank you for the info. Just have to be careful it doesnt freeze!

Hello! I have a heavily modified K40 (290mmx570mm cutting area, Z-table). I am still using the same tube it shipped with. When I received it, the “tube temp” thermistor was taped to the side of the tube. This placement, I believe, is probably not the best location since it is not measuring the water temp, but the surface temp of the exterior glass tube. I’m cutting 5mm ply at 10mm/sec and it gets through just fine, but I also notice the temperature rising (tube wall). However the water temp doesn’t seem nearly as warm.

My question is, should I move the thermistor to the water container rather than the tube wall? In other words, can the tube temperature exceed 30-35 deg C as long as the cooling water stays down in 22 deg C range?

I think the manufacturers just taped it to the tube for the customer move it to the tank later, but they didnt tell anyone. It´s my theory anyway 🙂

I only monitor the water temp and psu temps, water is the most important. With higher temp you are lowering the regeneration process inside the tube and lowering the life-span.

So dunk the sensor in the water tank instead, tube surface temp doesnt matter if you keep the inside cool.

I would keep water temp at 15-17c to keep regeneration process good. 20-22 you start to slow down this (less new gas is created shortening the life span).

Add some frozen soda bottles filled with water to your water tank, and increase the size of the tank to at least 20-25Litres, i use wine brewing buckets for my machines. Bigger tank – longer cut/engraving time without overheating, and if you add some ice packs you can both use it longer time and spare the life on the tube.

The tube was getting up past 32 deg C after just a few minutes of cutting, yet the water was basically the same temp as when I started. THANK YOU for confirming this! I have a decent stock of ice packs ready to go 🙂

Short cuts with 25-30 does not hurt much in the long run, but if you do it every day and for longer runs it will hurt.

Put the pump in the bottom and the return hose in the top just below the water surface – it prevents bubbles (air) and also mixes the water a bit so you dont get only super cold water 🙂

Hello,

First off thank you for this amazing site. It has been immensely helpful and helped me commit to getting into this hobby.

I purchased a laser that was cutting fine for the first dozen or so cuts and then stopped producing a beam that would cut through even 2mm soft plywood. I replaced the mirrors, lens, realigned, and set it for the optimal focal length and it still will not cut.

Thanks to your site I installed an mA-meter from day1 and I know I never over powered the tube and it has operated at no more than 22C.

With replaced parts I assume it must be the tube or the PSU at this point (but the mA-meter does show the same power that it had shown when it was cutting). Is there a way I can troubleshoot the tube? I have gone to the company that sold me the laser and I was able to get £100 refunded from them to avoid returning the cutter. If I need to buy new parts I am happy to do that. Thank you for your time and while I tend not to use AliExpress (lean towards Banggood) I would be happy to donate to your page if you have a link I have not seen. Even just for all the help this site has already been.

Put a bridge between P+ and GND connector, remove any cable located on the P+ before.

If you have power output and P+ is grounded (its a safety pin) and you see more than 5mA on the meter, you need a new tube.

I would suggest Yong-Li or Tong-Li tubes, you can find them on aliexpress, banggood or ebay too i think.

No donation needed, the ads bring in a few bucks to fill the fridge with Pepsi for long sessions of writing articles 🙂

So I went to try this just now and there was already a bridge (like those on HDD to determine slave drive) on the P+ and GND (PSU Type 2). There was nothing else connected to the P+. From day 1 of receiving the laser it has been bridged. The laser was firing away with this bridge in place back when it was cutting instead of just engraving but being unable to cut. The meter has been reading above 5mA since I first used it. Does this mean it is most likely the tube?

Really appreciate the tube brand recommendations. This site has been a real stress relief in this endeavor.

Yeah, if you have above 5mA you can rule out the flyback transformer (power often stuck below 5mA when they go + arcing).

I have TongLi and YongLi in all my machines, with proper care, good cooling and no overpower (max 15-16mA output) they can last for years, i think my oldest tube touching 4 years now and it has lost maybe 5-10% of the power.

Do not try to fire the laser more, when doing this the power tries to energize the tube but it cant, and you might blow the flyback and it starts to arc internally.

Cloudray has some nice tubes too.

Excellent, thank you. Do you have any links for the tubes to get you a kickback from vendors? You’ve been more help than the actual vendor of the laser so I would love to support you besides seeing ads on the side if I can. Thank you for your time and all your assistance.

If you are shopping on Aliexpress you can use any link here to buy one, and then choose another store. If you are shopping on amazon or ebay i dont have any links at the moment. But i´m happy if i solved your problem 😉

Bought and installed the new tube (thank you). While I was test firing it to re-align everything I noticed that the power does go over the previously mentioned 5mA…but then drops back down to below that 5mA. I guess I did not fire it for long enough before. With it starting strong and then dropping back down could it be some capacitor/flyback issue? I think I will still replace the whole thing. I just want to get back to trying to cut cool things for people! Thank you again for your help.

Make sure to push the test-button on the PSU, you can hold it for 2-3-4 seconds, just make sure to watch where the beam hits – i have a nice hole in my kitchen wall after i didnt look ?

If it goes down below 5mA it´s often a signal that your PSU is not working correct.

Go over all cables once more, make sure all crimps and stuff are really good and no loose cables or crimps, and that you have proper grounding to your wall outlet. If you have 3 prongs in the wall, make sure the 3rd gnd wire inside your machine has 100% good contact with the metal case of the machine, some chinese manufacturers put on plastics washers, as they dont have similar grounding as we do in Europe or North/South America.

If you want, you can use your phone and record a video and put up on youtube as unlisted, send the links here in comment (i will not publish them), record the purple beam inside the tube, and record the mA-meter so i can see how it reacts when pushing test button.

Hello,

I went over the wiring and everything looks solid. I have a 3 prong wall outlet and there was a plastic washer so I will be taking that out. What gets me is that this thing worked fine for half a dozen or so cuts after purchase. That is how I know that at 8% (I believe around 5mA) I was able to previously cut the 2mm soft plywood. After checking the wiring the power is staying above 5mA (thank you). when I turn it up that high and with the new tube it is doing better but while it engraves well it isn’t cutting unless I am at 10mA+ and moving at around 5mm/s. This is for that sam 2mm ply that previously cut at half that power easy.

I have checked the focal length by cutting something at an angle I and I pretty bang on. Is there anything else that can be impeding the laser’s power? I have new silicon mirrors and a new focal lens in the machine (feel like I am getting closer and closer to a Ship of Theseus situation).

I checked the troubleshooting guide you have and did not see anything about this problem. Since I have the money, would you recommend I just swap the PSU for an HY-T50 and start from scratch (rewire)? Thank you again for your time. Depending on your recommendations I can also easily take you up on your generous video posting suggestion. I will say when pushing the test button the purple beam is pretty much instantaneous, and the mA meter now holds steady.

Tube differs between each other, so 8% earlier might be 6% now, or 11%. You really need to have a mA-meter installed if you dont have one.

Swapping to a HY-T50 or Myjg-50w is always a good upgrade, sooner or later the stock PSU will go boom boom.

I have installed and sold over 200 HY50´s and only have 3 returned to factory. They are rock solid. You can find them on ebay, aliexpress and amazon. Just grab a 24v/4A little PSu too, not built in the HyT50

Thankfully due to your site, I installed an mA-meter before I even fired the laser for the first time. It is how I was sure I was not firing the tube at too high a power level. Thanks to your tips I have been able to get it to cut somewhat and I believe now a lot of power is being lost due to some reflection going on in the laser head (getting huge ghosting line now). I also purchased a new Cloudray laser head that I will be using your modification guide to adjust before I mount it (I have to widen the bracket anyways).

Power supply: The HY-T50 has already arrived and I have a 24v/4A little external PSU from other projects. I was planning on installing it after reading your 24v external psu article.

I noticed that you have an “upgrading the power supply to HY-T50″ article in your upcoming articles listing. Is there anywhere I could currently find such a guide? The labels on the HY-T50 are different from the stock PSU and I would rather not fry something that was easily avoidable. Even a wiring diagram would I think get me where I need to be (I have “PSU TYPE 2 pinout). Thank you again for all you have already helped me with. You have an American in Scotland in your debt.

You mentioned mirrors earlier too, (edited, i remember wrong, SI or MO is perfect mirrors). Grab a set of MO-mirrors next time and a ZNSE or GE lens. You are as you suspect probably hitting inside the laser head and it will cause ghosting as you seen.

You can test this very quick – do a test-cut and stop, touch the laser head nozzle – if its hot you are hitting inside. The beam itself is not hot – only when it hits something.

You must be psychic. I also replaced the mirrors with SI mirrors. I picked up a couple of lenses from ebay but unfortunately cannot remember the brand. Thank you for the tip on the nozzle, I will keep that in mind when I try it this weekend.

Your tip about the hot nozzle head really helped! I was not getting anything after adding the new laser head but I could feel how hot the head was getting. I have the beam coming out the nozzle now and am hoping to align in better when I next have time off. The alignment is all over the place since I replace the head and the new one sits higher than the old one so I raised everything else a bit too.

Good to hear it helped! Correct, you cannot use the same plate holding the new type of head. Its 8mm lower.

If you have a 3D-printer i have a file here on the site to download for these.

I do have a Prusa but I was able to drill out the original plate and then adjust the height of all the other mirrors. My main alignment problem at the moment will be figuring out how to get the beam centered coming out of the nozzle. Since the mirror in the laser head is not adjustable that is proving to be trickier than I anticipated.

Use paper as shims between mirror and head. Lift the mirror, put in a piece of paper and see if it helped.

You have to identify where the beam leans to put the paper in correct spot.

Hi,

I have a dual head Chinese laser, with 150 watt reci tubes, today laser 2 it not cutting through (3 mm Mdf ) amp gauge reads 6mA , laser 1 is fine and working well, im assuming it’s the tube failing, as they are both running off the same PSU.

Is there a way to test this first.

Cheers

Try swapping the output positive cables form the PSU from tube 1 to 2, and see if the problem moves. If the problem is still there, the tube is on its way out.

My Laser has changed the beam spot from TEM00 to TEM01 , i have used the Laser with 0 degree water this Winter and after some jobs the beam is like a 8

Do you get 01 on all power levels? 0 degree is not a big issue, it´s close to freezing and can cause problems with the glass but not much power gain or loss on temps like that what i have seen in my tests.

I can´t rule out the temps being a issue or the cause though as i never tested it long term at those levels.

Tem01 is pretty common on low power when the tube is on the way out though at power levels you could use before, or with very conductive coolant.

If you still get 16-18mA on a 40(32-ish real) watt tube but donut-shaped beam i´m pretty sure its the tube or the output lens inside the tube.

If you are stuck at 4-5mA no matter power setting it is the power supply causing it.

If you want, send me a email with different power levels and show the beam shape on a piece of tape out of the tube to help@k40.se

Hello can u help me understand why my laser skips when powered above 3-5 ma. Is it losing power. The best is still slightly purple

99% probability that your transformer is dead.

You can test and follow this guide: https://k40.se/k40-laser-troubleshooting/no-fire/

Do the test suggested there, putting a small wire between P+ and GND to confirm function of the tube.

My laser tube failed on me, I’ve now replaced it and it fires on test. But for some reason I can’t connect to my laptop anymore. I’m running windows 8 with K40 whisperer. Any ideas?

Try another usb-port. And check if you see the machine pop up in device manager.

That is a start. After that it´s time to check voltages to confirm the board has 24V power.

What are the symptoms of an overheat? Changing from TEM00 to TEM01? Or just a reduction in power?

I had kink in the coolant line and the temps spiked to what I would imagine to be “catastrophic levels.” Something like 45C…

The laser still fires and can still cut plywood to some extent, but nothing like when the beam was in TEM00.

I guess I’m wondering if the change in the mode equates to loss in power or if the TEM01 mode distributes the power into the classic donut shape.

Also, what is it that actually causes the change in mode? Does it have anything to do with the gas inside the tube, the optics inside the tube, or the physical shape/construction of the tube?

Catastrophic failure often occurs with loss of coolant, overheating the tube and cracking some of the internal tubing so the coolant leaks out in the chamber around it – this often kills the tube completely right away.

Overheating for a longer period of time – let´s say 40c water under 10hrs of runtime will show up as a lowered output or completely dead tube, there is so many parameters involved i can´t show a schematic of what will happen.

When the laser is discharged the gasses are dissociated from Co2 to Co and O2 (there is more stages here but keeping it simple). The dissociation is quicker than the recombination if the gas mixture is not cooled, in our case, with water through the tube and if the water is hot or not there at all the recombination will slow down – and with time affect the output. This reaction is never 100% or 1:1 ratio, there is always a loss. Hot coolant, no coolant or overpowering the tube lowers this ratio – less Co2 to excite when discharging the laser – less Co and O2 (with Nitrogen, xenon and others) to recombine to Co2 again.

45c for a short period, let´s say minutes should probably not kill the tube. I would suggest some “regeneration runs” – Low power, high cooling and let the recombination “work” for 10 min. Engraving or cutting for 10min at 14-16c coolant temp at maybe 5mA have shown better performance after similar issues.

Also take a look at the end lens in the laser tube, when they overheat the glue tend to soften up and moving the outer part of the tube – this can give very strange beam shapes too.

The TEM is not my area of best knowledge, i have a basic understanding of it but nothing to write home about.

What is the recommended % of laser power for quality of clean rubber engraving for making a personal seal with complicated logo without causing damage to the CO2 laser tube?

This is very different between machines, it depends on optical qualities, how good the machine is aligned and so on how much power you need. The best approach is to test it bit by bit, start at 20% and 150mm/s and see what you get – if its too light, lower the speed or increase power. But i would suggest installing a mA-meter, the %-meters are not very accurate, you are over-powering and damaging you tube already at 50-70%. A mA-meter will tell you the real power.

So, 1 px/mm and 1 pass is enough or the best is 2 px/mm and 3 passes at the 25% power and 200 mm/s for the Kehui KH-3020 Laser Engraver to engrave a 40mm personal rubber stamp?

Impossible to confirm or deny, even if you put two identical machines you have side-by-side, they will need different settings. You need to test it on the material you have. The machines are different and rubber stamp materials are different from different manufacturers, so the only way is to test it. I would go 1px/mm for everything.

Bonjour HP Persson

Pour Un Bon fonctionnement Laser CO2 100w

Quelle Température ?? °c

Quelle Puissance Max ?? mA

Merci De Votre réponse

It may be different between manufacturers, but above 20Celsius is not recommended. Some tubes, like RECI is made for 20-25C max. Max mA depends on the manufacturer, most 100W machines has 24KV output, max mA is then 28mA. If the output is 16KV, max output is 35-38mA – check with the seller for exact data.

Un GRAND MERCI

pour la réponse

HP Pression

Super

When you say the best temp is between 15 and 20 degrees , does that mean there is a loss of power when running the tube under 15 degrees? Was just wondering why this would be the case… cheers

Lower temp will introduce condensation on the tube (dew point), that might cause arcing in a bad situation. You do not gain anything with having the coolant colder than 15 either, just bigger risk of cracking the tube if you get a hot-spot or a flush of hotter water.

Ok Thanks, I see your point. Will definitely keep that in mind.