This guide will help you identify and solve most problems with your laser machine not firing the laser beam.

Make sure your K40 turns on and homes to zero position.

If it doesn´t, check the fuse in the rear power connector before continuing.

Step 1

Turn on your machine.

Open the lid on your panel and push the test-button located on your power supply

Go to Step 2

This part is avalible at ebay, aliexpress or in our store. Make sure to visually identify your type of rectifier before ordering one.

If you want to step your game up a bit – upgrading to a HY-T50 is a good upgrade, this PSU does not have the issues the K40 power supply has.

Avalible on amazon, ebay and aliexpress.

If you do not get any movement on the mA-meter at all its probably the tube.

If you get a small movement on the mA-meter, 3-4-5mA – it´s most likely your PSU.

The flyback transformer might be the issue but there is no guarantee it will solve your problems.

I suggest upgrading to a HY-T50 instead of buying a new K40 power supply (not sold by us).

This guide cannot identify exactly your problem any closer than this.

Things to try:

– Make sure you have grounded the machine properly – see this article

– Check all internal connections for breaks, bad crimps or loose cables.

Step 2

Turn on your machine.

Push the test-button on your panel, and/or through the software you are using with your machine.

Try this:

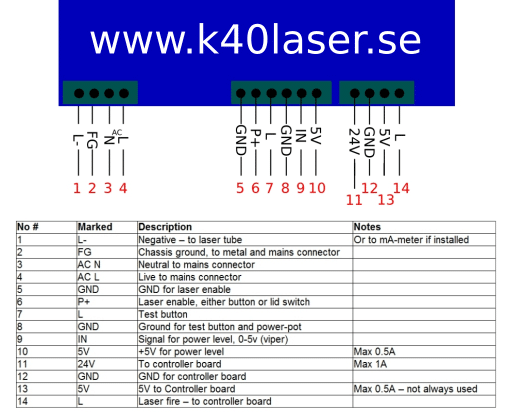

– Put a bridge or small cable between P+ and P-(gnd) and test the machine again. If it fires it´s whatever security solution connected to these pins that are your problem.

Often a flow sensor is connected, inspect it and sometimes it can be adjusted to allow for less flow/pressure.

Check this picture for pinouts

If you have upgraded your controller:

Make sure the power supply, any extra 24V power supply and the controller is grounded to the same point, often the ground bolt in the back of the machine.

You can also put a small cable between the laser PSU ground to the screw terminal ground on the Cohesion3D controller.

Same solution with other controllers, make sure they are grounded on the same spot.

Hi,

firstly thank you for this great site, its one of the reasons I felt comfortable buying this machine over a more expensive option!

my machine is only firing via the test switch on the power supply, this would imply that there is a safety system stopping the tube from firing through its usual method.

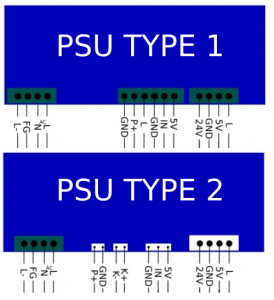

It seems my particular K40 does not have a flow sensor at all and has the type 1 power supply above.

If I wanted to add a flow sensor would I install It to P+ and GND? (Is this essentially the Water protect connection?)

in the mean time is it safe to just bridge the system with a standard jumper board wire?

Sorry for slow reply, but yes you can bridge P+ to gnd, or add water flow sensor, or even other stuff that breaks the connection, like a lid-switch, or door switch if you have kids – if they enter the room the laser cannot fire and similar.

Hello, I just got my k40 and did a cohesion board upgrade to use lightburn on a Mac.

I have everything set up properly (to my knowledge) but the laser only fires when using the control panel button, and it will fire in light burn if I depress the little red bypass switch on the psu. I don’t seem to have a water flow switch, and all my other tinkering with the installed items doesn’t make a difference in operation.

Is the only solution to put a jumper wire from the occupied GND to the adjacent unoccupied P+ on the PSU style 2?

Make sure you have a GND wire between the board and the PSU.

And have a jumper between P+ and any GND.

This site is great – certainly gave me some things to look for.

I have been given an upgraded K40, with an HY-T50.

When pressing the test button, with the “IN” voltage at anything above 1.3V (set by the potentiometer), the current meter goes over 30mA(hits the end of the meter), the tube generates a pink plasma, but doesn’t lase.

This setup has sat in someone’s garage for a period of time, and both the Power supply and the tube have less than 10 hours runtime on them (according to the previous owner).

My question is – is the fault more likely to be with the PSU, the tube, or something else?

Edit – and is there anything else I could try to narrow it down some more?

It might be a cable issue depending on how its wired.

The test button on the PSU always goes full tilt no matter what you have set the potentiometer to.

The test button on your panel should be connected to GND and LO on the PSU, and you should see the real power set from the pot here.

Make sure the pot is connected to IN with the variable voltage – not the wrong side of the pot.

If you still have +30mA, i would actually think the meter is bad. Double check with a multimeter, and be safe, keep one hand behind your back and never hold the probes with your hands.

Thank you HP – I connected my DMM in place of the ammeter, and found that the test button on the PSU does use the IN voltage, as well as the test fire button.

When I had this in place, it did not misfire as much, but sat quite happily at 17.5mA – with a nice pink/purple plasma down the centre of the tube – I can’t tell that it is laseing though – a piece of paper placed before the first mirror showed no signs.

However, occasionally, the plasma will arc to the outside of the tube, and the PSU will make a squeal/fizz. I didn’t catch this reading on the DMM, but this is when the Analogue meter hits the endstops.

If you see more than 3-4-5mA on a test fire its most likely a dead tube.

The plasma you see is only the excited gasses not the actual beam, if the gasses are in wrong proportions or one is missing you only have a nice glowing tube for decoration 🙂

Do not test fire more, every time it arcs you are affecting the flyback converter and with time you will burn the PSU too.

Grab a TongLi or YongLi tube, or look at Cloudray versions. Keep it below 18c temp when using it and it will last for years.

Edit: One thing that can happen sometimes is the last mirror inside the tube gets very dirty or loosen by heat so its not sending the beam outside the tube, and sometimes the end cap of the tube falls off and needs to be glued back. This can in rare situations cause this effect too.

But my bet is a new tube is on your todo-list.

I’d just like to say that a new tube *did* solve the issues, Thank you!

Sweet! Have fun with a working laser machine 🙂

Hi I am in desperate need for an exhaust fan upgrade when I cut acrylic I’m basically dying slowly from all the fumes and smell that comes from it do I have any suggestions on what to do or buy?

Most important with acrylic cutting is to seal up the machine. Right now you have to many places the fumes can get out and too low speed on the exhaust. Also make sure the exhaust pipe is outside the window, just not up to the window so you dont get a back-draft.

I can see you are visiting from Sweden, check out Biltema exhaust fans, i´m using the one with product-id: 43-344 and some 26-4503 EDP rubber to seal the lids. You can find similar types on Jula, Bauhaus and similar places.

Check out this article for more details about sealing the machine and optimizing the exhaust: https://k40.se/k40-laser-air-smoke-assist/

And this link: https://k40.se/k40-laser-exhaust-filtering/

Cant seem to find the exhaust fan on biltema so I have any link or alternatives

Sorry, wrong product-id, here´s a direct link: https://www.biltema.se/bygg/vvs/ventilation/ventilationsflaktar/ventilationsflakt-100-mm-2000047228

My question actually is why does my k40 give higher mA when test firing compared to running a program with the mA knob in the same place

When running a job the laser is pulsed on-off very quickly and the mA-meter can´t keep up with the changes and shows a lower mean value. It depends on how advanced the job is how far away the meter is from the test pulse.

If you do a cutting job it should stay roughly on the same value.

Ok 1last question , can I put tape around the knob, test fire it at different mA, write down the mA value on the tape and use that to know what mA I’m running the job with?

Yeah, its a common trick to keep a list of what power is needed for lets say 2mm acrylic, or 4mm, or different settings you need for engraving different materials.

When it comes to slate, some wood veneer and ply the power might need to be adjusted to the material as it can be different from time to time. But it´s good to have a list with values to start from.

You can also check out this, its a better control of the power with digital numbers. Instead of tape you have a display. And you can remember 2.00 for slate engraving, or 3.1 for acrylic cutting. Not expensive and easy to install -> https://k40.se/k40-laser-upgrades/analog-power-setting/

Hi so i have finally grounded the machine properly and it’s working now. I do have another problem now wich I don’t know if it should be like that but when I’m trying to engrave slate coasters i can’t seem to control the mA it just does whatever it wants anyway sometimes and then it spikes upp and then down and simply does this all the time , why can’t I have a consistant power? I try to have it at 5-9mA but it does what it wants, turning the knob adjusts it only sometimes. I appreciate the help

It should not go above 9mA if you do a test-pulse at 9. If it does, something strange is going on.

Hi so i bought my first ever laser and I’ve been googling everywhere on what and how I can solve the problem.

Im having a constant flow of current through the whole chassi , like static and tingeling when touching the metal frame. It won’t stop iether its a constant thing so holding the frame for 6minutes gives u that tingeling/static feeling for the entire 6minutes.

I need help plz

There´s two reasons. 1: Your outlet is not properly grounded. 2: Your internal grounding is bad. Check out the internal ground point and make sure its touching bare metal, and also check the internal ground cables marked as G from the power supply. Bigger article here: https://k40.se/k40-laser-electronics/grounding/

Alright I will check that out, I was almost certain I have grounded outlets. I also do change the ground bolt just like the images and scraped to the bare metal. So I’m almost certain it has something to do with my outlet

Hi. Maybe you can help me out. I have a k40 doing something odd. Mine is a older one so I just have a digital % setting. Up to about 20% it engraves. Going past 20% you lose any beam, kinda it still does a little of the outline of like a letter for example but not the inside.

As you can see from the photo. It starts at 15%, moves up to 30%, then back to 15%, then back up. But the higher you go the less you get. 30% might still get faint edges, but 40% & up gets nothing.Using the test button on the PSU gives same results. Below 20% you get a dot, above nothing.

Mine has a model A PSU. There is a beam in the tube. I’m stuck on if it’s the tube or PSU. Thanks.

Very hard to tell without a mA-meter. You can do it with a regular multimeter but you have to be very careful not touching any probes or metal when test-firing.

You can do it from the negative cable coming from the tube, put the multimeter to measure resistance and one probe on the cable from the tube, and the other probe to the pin on the PSU where the cable were located. But make sure you can do this without holding the probes, use clamps or tape to make sure you do not touch anything, and use a wood pen to push the test-button on the PSU. And keep one arm behind your back – just to be 100% safe you dont electrocute youself, your heart will stop – or at least make your hair look funny.

If you power never goes above 3-4-5mA its your PSU, if you can see up to 18-22mA, its the tube.

Another test to check, P+ and P-, if you have a flow meter on that one, when they go bad they can fluctuate a bit so it allows the tube to turn on-off-on-off-on-off very quick and it can cause this effect too. So remove P+ and P- and put a small cable bridge between and test again.

Thanks. I’ll look into setting up a tester between the negative wire coming off the tube & where it connects to the PSU to see what mA reading I get.

Flow meter is bypassed. It’s the 2 pin connection to the right of the test button. But it’s not going on-off-on-off. It’s the beam slowly goes away as you increase power.

In that photo it’s not a constant power. The top is about 15%, then I upped the power using the panel to 35% (missing part), then turn it back down to 15% (started marking again).

So I guess what I’m asking is if the tube is going out will it still mark at lower powers but the beam get “weaker” as power increases. Or is the PSU HVT able to produce some mA at low power settings (5%-20%), but failing as you Raise the power up resulting in no beam at about 30% power & up. This is at the end of the tube also. 15% mark on tape at first mirror, 35% no mark on tape. Thank you.

A bad HVT starts arcing to ground when you over-power it, either inside the PSU or on the positive pin on the tube to case metal ground, roughly 3-4-5mA, what that is in % is very different between machines.

Hello first of all thank you for your amazing work.

It seems that I am in the case where I have to put a bridge or a cable between P+ and P-.

I don’t have much knowledge of electricity. What type of cable should I use?

Thank you in advance for your answer

Any cable works, 1-2mm2 is enough. Its just a ground connection without power to signal the PSU its safe to fire the laser.

Okay thank you so much.

At the level of the P- there are two cables, white (top) and pink (bottom).

Which one should I unplug to set up the connection between P+ and P-?

You need to follow the cables to see what it is. Often just a water flow sensor or lid switch.

Its safe to remove and replace with a small cable between.

First stop Mr HP you are a legend for answering us.

I tried to find the answer without contacting but nothing.

I got a new vevor K40(my second one).

PROBLEM: No laser beam at all (not even a little at 100%, nothing) even when using the test button. all I can hear is a buzzing sound from the PSU. no light on in the laser.

I cannot see any cracks on the laser tube.

–> I try to figure out if it is the laser tube or the PSU that needs to be changed.

Many Thanks

Beautiful community

I would suspect the laser tube. No light at all in the tube = no gases to be excited.

Even with the common issues with the PSU´s there is some glow in the tube.

thank you very much for your reply. a little spark appears at the top end of the tub when laser power is raised to 80%… and you can see the tunes of the water pomp moving when the laser is activated.

I will change the tube. should I upgrade straightway to a better tube? any recommendation?

Go for a TongLi or YongLi tube. Or look at Cloudray laser tubes with a metal end (often gold-ish colour) they are really good.

I only use TongLi and YongLi tubes here and the oldest machine touching 6 years now with the same 50w tube.

If you want to upgrade, go with a 50w tube instead of 40w. In the future you maybe want to upgrade the PSU and then you already have a good tube.

There is no problem running a 50w tube in a 40w machine, just keep the power at 16-18mA to make sure you do not cause problems with the lifetime of the tube. (you will not get more powwer, but it will last longer).

I cannot thank you enough mate. a true legend. thanks

hello from Belgium

i bought k40 but the tube don’t giving power,(can’t see violet licht in the inner tube) thePSU looks good and i have High voltage on the kathode,The power controlboard works also good, when i go to 20% power, the HV on the tube jump over to the chassis, even with a veri good isolated connection

Most likely a dead tube. But check the ground first so its 100% perfect to be sure.

But, probably dead tube.

Hello, laser only fires below 12mA, but only engraves it wont cut any think material.. the light on the tube its like violet? what could it be?

If you cannot get abot 12mA it might be your tube going out.

Double check all mirrors and lens for damages too, and make sure you are in perfect focus, see this calculator -> https://k40.se/k40-laser-calculators/k40-laser-machine-lens-focus-calculator/

Mirrors look ok, if I put the laser at 15mA it starts firing the degrades to no firing during the job.

also now im hearing an arcing sound coming out the psu

If it arcs you need to stop right away.

Your tube is probably dead, or rather i can almost guarantee it.

Might be a very strange PSU issue, but i have never seen a 15mA fire with a bad PSU, so grab a new tube. I would suggest TongLi or similar. Cloudray on aliexpress/amazon has good ones too.

Hello, in 6 months I changed 3 tubes. I used it 25 percent digital and no more than 25 degrees. I asked friends and they told me to put an ammeter and not exceed 20 degrees Celsius on the water. After the third tube I ordered an ampere meter and a new 50 w tube. While waiting for the new tube and ammeter I decided to do a few tests with the old white beam but it works. For I uploaded a multimeter and it turned out that at 25% = 4ma 35% = 7ma 45% 11ma but at 35% or 7ma I have a beam that reaches the bed at 45% or 11ma does not come out of the tube to mirror 1. Only at 25% or 4ma I have a sound of electricity in the power supply. The question is because of the power supply do the pipes burn and can I put a 50w pipe on a 40w power supply

No problems with 50w tube on 40w psu, or bigger psu on less wattage tube.

I run 50w in all my machines and it works perfect, just keep a eye on a output to not over power it (which you cant with a 40w psu though)

Hello, I’ve used my laser for about 2 years now with no issues but I mostly cut fabric or EVA foam. Today I tried to but wood and it cut the test piece twice but then the laser slowly went away and now no longer fires at all. There’s no test fire…

Do you think it’s the tube? Could the water have been too cold and the laser too hot?

Cold water helps the tube, if its very cold (below 0 celsius) it can cause issues. But above freezing it should not causing anything with the laser tube, you might get cracks or hot spots but you should see water dripping outside the machine if that was the case.

Check your mA-meter, if its stuck on 3-4-5mA its probably a PSU-issue, if you dont get any purple plasma inside the tube at all and no beam its probably a new tube needed.

Tube often goes out slowly not very abrupt with the decreased gas content inside. PSU´s often go boom or gets stuck on 3-4-5mA.

Hello,

I have a K40. I was using it to cut hardboard. It work very well for the first 5 hours and then in the middle of the job it just stopped firing. I have done tests.and it won’t fire. I replaced the tube because it wasn’t glowing but after the new tube was attached it also doesn’t glow. Could this be the Power Supply or something else.

If you dont get any reaction at all on the mA-meter it´s probably the PSU, as you have changed the tube.

But if you get above 7-8-9mA on the meter, the new tube is also dead.

If you dont have a mA-meter, you can use a multimeter, just make sure to keep your hands away from cables when testing.

Hi,i bought some days ago a laser k40..While i was engraving a photo it made a warning sound and stopped firing..Now it doesn’t work at all…The mA-meter also doesn’t work when i push the test button..Also the tube doesn’t firing..Do you have any ideas??

Sorry for slow reply, you probably have a tube problem. Hard to say without inspecting and testing some more.

Is that normal??i used it only two times and then the laser stopped..first time i used it for align the mirrors and the second time was when i started to engrave…

No, not normal. Talk to the seller about tube replacement, sometimes they are nice about it. If it is the tube, hard to say 100%.

I talked to him..he told me to do some things and i sent him also some videos..When he released that the machine has a problem and it came to me like this he stopped answer to me…Now i don’t know what to do…I’m new and i don’t know how to solve this problem…

If you have any buyer protection, try to use that. Sometimes you might get a new tube or some % refund to buy a new one, or partial refund covering almost a new one.

If not, not much more to do than order a new laser tube. Which is not bad, as the tubes delivered with the machines are practically junk from the beginning, compared to a new TongLi or YongLi tube.

Sooner or later you need to replace it anyway.

But i cannot promise you your problem is the tube – but you have zero movement on the mA-meter and no output, it´s probably a damaged tube.

Just do a last check, push the button and look at the laser tube, do you see a purple glow inside the tube?

No…it doesn’t have purple glow inside….

Then its a new tube for you needed.

Hi…i changed the laser tube but still doesn’t work….

Did it work a second or nothing at all for you ? And you have the water connected so the tube is cooled properly too right.

Hi just trying to set up my new laser and align mirror. I can hear a buzz when i use the test fire and the fire from the power supply, no laser on my paper though.

Check laser output power on the mA-meter when you push the test button. If its stuck on 3-4-5mA its a PSU issue.

If you do not have a mA-meter installed its a bit harder to know, is the bussing coming from the PSU or the laser tube itself?

Hello. I get my k40 yesterday. I do all the recomendations and I calibrate my mirrors. Everything seems ok. But today I try my first cut. But the laser don’t cut with the software. I push the test button and the laser works perfectly. But corellaser or laserdrw just move the axis, but no laser appears. During the progress I have the pendrive key plugged to the computer. Thanks for your time.

Follow the article. You probably have a issue with P+ protection, see the article how to test it.

First of all, thank you for your time.

When I wrote the first time it was because I could not find the fault. I followed the article but nothing. I searched and searched until someone advised me to re-tighten all the connectors. I there it was. A connector on the nano M2 was incorrectly plugged from factory, even with glue. I cleaned, plugged in, and everything was ok!

Thank you very much!

Hi there,

I recently bought a second hand K40 which was supposed to be working ok. When I’ve come to set up the mirrors I’ve come across a problem. After about 10 test fires it started making a squeaking noise and the laser longer seemed to fire. I’ve placed laser card in front of the tube and don’t seem to get anything. Any ideas?

Thanks Chris

Tube or PSU issues, Check the mA-meter, if you only get 3-4-5mA its a PSU issue. If you still get 16-20mA its a tube problem.

This can also happen if the coolant water is really dirty, like tap water with lots of minerals, you should have a beam though. But its easy to just test with better water if you know you have tap water in there.

First off, thanks for being so nice by helping everyone.

I have a K40 laser with the front analog controls. When turning on the power, the machine homes, and the green LED on the power supply board lights up but I cannot get the laser to fire at all. I have tried pressing the “test switch” on the outside panel and pressing the test button on the power supply board which both makes the red “L” Led light up on the power supply plus a red light on the programming board light up but no laser.

My power supply has the 3 green connectors. I confirmed the two first wires on the 2nd connector from the left have continuity with each other as well as the 3rd and 4th wires when I press the test switch.

Do you have any ideas?

If you do not get a beam or buzzing sound when pushing the test button its hard to tell if your flyback transformer inside the PSU is gone, of if the tube is gone.

Do you have a mA-meter? does this one show any life at all?

There is a test to do, but you need a multimeter for this. It´s a bit dangerous though.

I don’t get a beam or buzzing sound when pushing the test button.

I do have a mA-meter and it didn’t show anything regardless of what what I set the current dial at.

I also took both wires off the laser tube and wrapped them around a tooth pick about a half an inch apart and no arc happened when pressing the test switch on the outside panel or on the PSU.

Do you have any other ideas?

That pick should have burned very quickly.

Open the PSU, check the rectifier if it looks okay, when they blow up they get a hole in them. Google for “rs207” to see a picture of a rectifier.

Also check the internal fuse on the board if its solid.

If you have power connected to the PSU, be very careful not to touch anything. Or leave the power out for a couple of hours before inspecting.

The rectifier visually looks great.

The fuse looks good and I’m getting continuity through it.

I attached a pic as well.

Looks good, it´s a tough one if its the tube or the PSU. As you could not burn the tooth pick my suspicion is towards the flyback transformer in the PSU (big white thing).

You could try to buy just the flyback, just make sure to get a identical one. Or buy a HY-T50/MYJG-50 power supply as a upgrade.

Test button on the PSU board disables settings and safetys and should give you full power as long as you press it, and burn the wood you put between the cables very easy. Try removing all cables except input power and try the wood trick once more, if that doesnt work i would go for a flyback or upgraded PSU.

I tried removing all cables except input power and still nothing happened.

If i upgrade to the HY-T50, do I still keep the big green resistor hooked up or remove it?

No remove that one, its not needed for the newer PSU´s.

First, great site and thanks for the wealth of knowledge and being so helpful!

I have a K40 in stock form that is very low on output. I replaced the power supply (as you mentioned) but I still have the low output issue. Its less than 1 mA when using the test button on the PSU (I assume this bypasses the control panel and gives full output).

Any ideas?

Its often the PSU or flyback if the output is stuck on 3-4-5mA. Can you check the color of the plasma in the tube, it should be purple in color, if its weak it might be a bad tube.

Sorry for slow reply, i´m on vacation 🙂

Hey, I have a blue 50w. It test fires fine. But will not engrave or cut even acrylic. It used to handle this material just fine. Orion motor tech said it was lightburn. I switched to rdworks. Changed to a new tube. My etching is so faint, even at slower speeds and higher power. The test fire works fine. Any ideas?

To me it sounds like the PSU is gone, or at least the flyback transformer. Its very common to get stuck at very low power output when the flyback is going bad.

My machine is engraving but suddenly it started to go lighter and lighter and now I can barely see what’s doing

This is often due to a bad tube, without proper cool water the gasses will wear out. Or with too much power.

Make sure you have a mA-meter to keep the power below 15-16mA. If you have one installed and it get stuck on 3-4-5mA there is a PSU issue, the flyback is dead.

Hello, maybe someone can help me… I have a adjustable table (for the right focus) and the mirrors were set with the ADC Method. It all Works fine but the laser cant cut anything. 3mm/s and 12mA and 5 turns – no cut trough the material ( 3mm Poplar). The laser only cut ca. 1mm deep inside the wood and then all the other rounds nothing happend.

Check your focus, make sure you have proper distance between lens and material.

Thanks for this guide, it made me find my problem. For me it was the door switch which was badly adjusted and not was not pressed when the lid was closed. Hope this can help anyone having a similar problem.

Hi. I’m having an issue with my K40 laser not firing. I got it a few months back but only just set it up. The test button on the power supply and it works but nothing else. I am no expert in lasers at all but everything seems to be screwed in correctly and nothing loose. I have attached a photo if this helps. Any advice would be apricated (dumb it down if you can) 😀

Remove the two first cables on the 2nd connector from the left. Its marked GND and P+.

Put a small cable between GND and P+.

Looks like pink cables in your picture.

Now you can use your machine again.

Inspect whatever is connected to P+, it can be a lid switch, temp sensor, flow sensor or something – this is causing your machine not to fire.

With this you are without security for example water flow, so make 100% sure you have proper flow in the laser tube before using, and replace the flow sensor or whatever was connected here.

Hello there! After changing the tube, upgraded the psu the machine cut like never before but…dunno why, it just cuts but not engrave! What the hell could be this time?? 😀 Thank you

Sounds like something with the controller, do you use the stock M2 nano or a upgraded controller board?

stock

If you can cut but not engrave, i would say it´s something in the software or the file you are using.

Try with K40 Whisperer or MeerK40t, and make sure you are using correct colors for the right method.

If you want you can email your file to help@k40.se and i can test it in one of my machines so its set up properly.

When I try to engrave, the laser head start to move fast in loop from R to L, firing until I stop the the machine.

Here my wiring to spot if I messed up something

Remove the bridge between TL and WP.

If it wont fire after that – add a bridge between WP and G

1) removed TL + WP bridge = nothing changed

2) removed TL + WP bridge and added bridge between WP and G = it works BUT I cannot control laser power, the display is OFF

Unscrew the LCD panel, make sure the only cables you have connected are 5V, G and IN. You can see letters on the LCD board what goes where. Make sure these are on the correct pins.

Remove the other 2 for now.

win! it was a wrong wiring…thank you mate! Can I offer you a beer? Do you have a tip jar?

Perfect! No tip jar though.

If you want the laser enable to work on the LCD, pull one cable from P+ on the LCD to WP, and the P- on the LCD to G. And you have the control back again.

Had a laser stop working mid engrave, figured it was the power supply so I changed it out but nothing. Changed out the laser tube and nothing. Put a jumper across the connection for the flow detecter nothing. I’ve checked all my ground wires can’t find any issues. Everything seems to work and be in working order but the laser will not fire.

Press the test-button on the power supply, this bypasses everything (or should at least).

If you still have no fire of the beam, and no reaction on the mA-meter i would start over with checking the high voltage connections to the tube and make sure they are good.

Hello, K40 all aligned and laser firing onto all mirrors but nothing coming out the cutting head. Take the cutting head out and test fire – all works – put the head on again and nothing – HELP

You are hitting inside the laser head. You need to adjust the head. Do you have stock laser head, or a upgraded version?

Thank you for replying. I have reverse aligned using a adaptor and laser. The laser fires center on the laser head mirror. Taped it on all mirrors and marks clear center. Yet not firing through the head. Head inspected for blockage and none found. Lens good. The laser has been used less than an hour. Switched out the Nano for a C3D and running Lightburn.

You can test this: Remove the lower nozzle part and put a piece of tape over the hole, test fire in each corner of the machine and look at the tape. You should have 4 spots in the middle, if not you are not aligned properly.

If you have the stock laser head – check out the download menu here to find a tool helping you to see if the beam hits center on the lens or not.

My K40 will only fire if the potentiometer is turned to maximum. I’ve metered the potentiometer and I get a smooth 0-5V as I turn it up so I don’t think that’s the issue. Any suggestions?

What do your mA-meter show? if its stuck at 3-4-5mA you have a blown flyback transformer.

If it shows 18-20mA – tube is gone.

More inspection needed though to be sure what it is.

If I hold the test button down and start the power at 0 the meter does nothing and I get no fire. As I increase to near max power the laser suddenly fires and the meter reads 22.

I cannot promise its the tube, but it seems like it.

If the flyback dies the power almost always get stuck at 3-5mA and you get a weak dot.

You can look at the tube too when pushing the test fire, it should be a pink-ish color inside the tube when firing. If it is very weak in color or almost nothing, it´s the tube that have died.

I get the pink light but only when I finally turn the pot up enough for the laser to fire. Once it fires it cuts but I can’t control the power. If I try to dial it down it just stops firing. There is no adjustment. Seems like it’s full or nothing. Trying to figure out what to replace first. Tube or power supply. Maybe both?

Pushing the test-button on the power supply, does that give you good power? Test-button on the PSU bypasses the potentiometer.

Hard to say, power supplies often go boom and stops working 100%, or get stuck at 3-5mA. Never seen one that only works on full power

This is strange. The PSU test button seems to work the same as the control panel test button. The laser will still only fire if the pot is turned to max…even though it’s supposed to bypass the pot.

Please can you help me, im almost certain it’s a flyback issue it will literally only let me have 2,3 or 4 ma, but the laser will still penetrant 3mm mdf with just a short 2 second blast at like 3ma

If its stuck on 3-5mA its 99% a flyback issue.

Hello

Starting today i have a verry strange problem with my laser.

When the beem hit first mirror It take a rotund shape but with a empty middle, in the middle the beem seems to have no power, all the lens ar verry clean, What i must do?

Thx

Try with more power, when tubes start to go out they tend to have a donut shape on the beam. If you get this at 8-10mA your tube is out.

It can also be the lens inside the laser tube, use a small mirror and look if its dirty.

Thank you for replay.

This tube have 200_250h is not so old, lens inside tube is clean… i have try with 50% and i have the same result and a verry bad one in final product.

Also i noticed beep coming from source When i engrave.

Tube is gone probably.

It might be the flyback transformer, its a cheaper part to replace to take a chance on.

Tubes will die quick if the water temp is above 20c and if you use more than 18mA longer time, a tube can die after a day, week or month depending on how often its used.

I bought K40 less then two weaks sgo.

Laser won cut. Alignment of the mirrors is good, focal point is also good. It worked well in the begining, I was able to cut 6 mm plywood with 40% power and now it wont cut 6 mm plywood even with 90% power.

I cleaned lens and mirrors, including laser tube outlet mirror and still haven’t solved the problem. I tried to readjust the height of the table, but it didnt help either.

At 10% power i hear funny sound from power supply. At bigger percentage of power it just burns material without cutting it.

Is there any solution for this? Maybe changing flyback could help?

Yeah. this sounds like a flyback issue. Change it, or upgrade to a HY-T50 PSU and you will never have this issue again.

The grounding is very important are sometimes a contributing factor for flybacks going up in smoke. Double check the numbers on the bridge rectifier too, if its less than 4A and 600V you need to upgrade it, some PSU´s with 1 or 2A rectifiers are too weak and burn out either the rectifier or flyback – or both.

Open the PSU and look at the flyback, so you order a identical one – count the cables in the connector and the orientation of it to order a identical one. There is different types and they dont fit if you order wrong type.

Thank you very much on really fast answer.

There is sign ‘GBU 610’ on my bridge rectifier and I found out that it can go up to 1000V and 6A so it should be ok.

I will try to replace flyback and hope it fixes this problem.

One more thing about upgrading to a HY-T50 PSU. It wouldn’t cause a problem because my laser tube is 40w, and HY-T50 is for a 50w?

No problems, i use a T80 on my 40w, its the output mA that you should watch. Always have a mA-meter installed and keep power below 16mA to make sure you are not overpowering the tube.

If you upgrade to a T50, you need a 4A, 24V psu too for the controller and steppers.

One more thing.

If I upgrade to T50 do I also need to change flyback or T50 has its own flyback included in itself?

T50 has a built in flyback of a different type so no need to buy a extra flyback. You can buy a T50 and a 24V, 4A extra PSU and you are all good to go.

Thank you very much.

I ordered T50, mA-meter and 24V, 4A extra PSU.

Next upgrade is probably AK-47 instead of laser tube. ?

Thanks again.

Perfect combo, we have sold 200+ machines in Sweden with HY-T-series PSU´s and i think there is 9 or 10 that had issues in 8 years. With the stock PSU almost 100% gives up 3 months to 1-2 years.

I only have HY-Txx PSU´s in my machines too, never had any issues at all.

Coming a guide shortly how to upgrade to T50 and 24V external PSU here.

You just red my mind. I was going to ask you how to upgrade to a T50 and 24V external PSU.

Check this url: https://k40.se/k40-laser-buying-installing-upgrading/

You can add your email here to get a notification when a new article is published. No ads, no newsletters – just a notification.

Great. I subscribed just now.

Thank you for your work.

T50 just came to my door and i dont know where to start. I am not good with electricity and I dont want to start without you.

Here is photo of my PSU:

https://ibb.co/PtwL5xb

Here is photo of my T50: https://ibb.co/dGSgJqJ

Extra 24V PSU is the same that you used in one of your guides.

You said that you are making a guide on how to upgrade to T50 and external PSU and I am stuck without it because anything i find on internet doesn’t seems to help.

I have been on hospital for back surgery a bit but starting to move better now, so the article is delayed at least a week more.

But it´s pretty simple, you can check out a reply i wrote in another comment thread. If you still have questions, feel free to email me at help@k40.se

https://k40.se/k40-laser-upgrades/psu-upgrade/#comment-39981

Oh, I hope you get better soon.

I will try that.

Thank you for answering and stay healthy.

Hello, I recently bought a power supply from aliexpress, a laser tube from aliexpres connected everything and started checking the operation with the test button from the control panel. It seemed to be fine but after a while there were cracks as if sparks were jumping over, until at some point there was smoke from one controller on the nano board. I ordered a new nano m2 tile along with the control panel and plugged everything together and to my surprise I still heard a crackle every now and then. Moreover, when I changed the old power supply, the same thing happened. I finally insulated the metal parts on the tube and the crackling sound stopped but the laser power is weak. The beam does not reach the last lens and when I increase the power more, it only gets a small dot, on the 1st and 2nd lens the paper tape is nicely burned. And even after holding the test button for a longer time, the laser would stop. I don’t think I can see the plasma beam inside the tube but somehow burns the tape on the lenses

I have a K40 with digital control … The laser was used for about 5 hours in half a year … It didn’t go over 50% it was mainly used at 35% … Now I have a problem .. the laser has a very weak fire … and only works up to 22% if I walk over no fire … how do I know what my problem is … power supplies or tubes … or maybe something else..

I contacted the seller … but they do not respond ….

Thanks

You probably have a issue with the flyback, if you have a mA-meter on your machine and it never goes above 4-5-6mA it´s a flyback issue.

I would suggest spend a few extra dollars though on a upgraded power supply and you will have less problem with this.

It can be the laser tube though, you really need a mA-meter to know whats going on.

ok … what do you suggest to improve that laser … and how to install the mA meter and which model do you suggest … if I change the power supply which model do you suggest and how to install it … I currently have 3 connectors …

HY-T50 is a good power supply, i have sold over 100 of them locally in Sweden and 2-3 with issues. Pretty cheap on Aliexpress or Ebay. I use it in all my machines too, never any problems.

mA-meter just a regular 0-30mA meter, found at ebay or aliexpress. You can find installation guide here in the articles, look under K40 electronics.

Ok. I’ll do it .. Thanks ?

Hi, so I just got my k40 and set everything up and went to test fire and got nothing.

On a hunch I put a piece of tape over my fixed mirror in the back and the laser tube did indeed fire and mark the tape. So does this mean that the mirrors are just terribly out of alignment? Like so out of alignment that the bean is not reaching the laser head?

Also ever time I turn on the machine the gantry moves towards the front of the machine, eventually it will try to keep going and make a grinding noise. Could this be one of the end stops?

Thanks

Hunt the beam. Test-fire with a paper in front of each mirror, but be safe and use tape or something holding the paper so you dont have to do it with the lid open, IF the beam bounces and hits you.

Most common issue for this is hitting a edge or inside the laser head due to bad alignment.

If it grinds, like skipping on the belts you have a problem with the end-stops. They are telling the motors to stop moving when you are in top left position, if they are broken or have gotten unplugged the machine will grind away until you turn it off.

Follow the cables from the end-stops back to the controller, look if they are connected properly. If they are, make sure the small metal tabs are not bent and fits inside the black little part on the end-stop.

Ok, thank you so much. I really hope I can get this going without spending more money…

Send a email to help@k40.se if you need step-by-step assistance with checking the end-stops. The help is free and does not cost you anything.

We provide free help to find out problems and issues others have to write better articles.

Hi HP Persson!

I just discovered your page and I am excited! Much information and detailed articles. Thank you!

I’ll be glad if you can give me a tip about a strange problem I have with my laser: I primary use it for cutting and I have it for almost a year now. Everything was good till last week. It works for 4-5 minutes and then while in the middle of the job the laser won’t fire. However the amperometer is working and turning ON and OFF depending on the job. Now the strange part: If I move the potentiometer all the way to 100% (while the machine working) leave it for 10-15 seconds there and returning it to 20% (where it usually works) the laser starts firing again and the machine works fine! However it will work for 3-5 minutes and then again the same problem. I am not sure what is causing it… I use distilled water, the mirrors are aligned. Any ideas?

Thank you in advance!!

I would bet you have a problem with the flow sensor, if you dont have one make sure you have a bridge between P+ and GND (P-). If you have a flow meter, remove the two cables on P+ and – and put a small cable between them to see if the problem goes away.

If the problem goes away, your flow sensor is bad – some types can be adjusted by turning something inside them to make them more sensitive for the water pressure. You can also upgrade the pump to a better one to have higher pressure/flow.

See this article for a picture of the pinouts: https://k40laser.se/diy-how-to/k40-laser-cutter-power-supply/

Hi! Thank you for your detailed reply. My machine doesn’t have a flow sensor. I tried a bridge as you suggested but nothing happened. Still the same problem. As far as I can tell the cables from that positions lead to the laser switch that works. Also the problem just got weirder. The laser fires at all power percentages but the beam only hits the target when I run the power at 20-30% (that’s 5 to10mA). I thought that there was an arch inside the laser tube when firing but I can’t see anything. Thankfully I have another K40 laser and I can do my work. I have a love/hate relationship with those machines :p . Any comments are appreciated.

Try this

Put a bridge between 5V and IN on the PSU.

Try running it now. But be aware – this bridge will cause the laser tube to fire 100% all the time so keep hands away.

If this works, your potentiometer is bad. Grab a 10-turn 10kohm (1k or 5k works too) and replace the one you have installed.

If it only works half way or just on different power settings it might be the potentiometer. It might be a bad tube or flyback too but i dont think so.

The beam inside the tube you can see is just the plasma, it should dance a bit around the negative ring connected to negative cable.

OK I tried the bridge but no luck. I can see the amperometer reach around 20mA and the plasma inside the tube but no laser beam exits the tube 🙁 Also I tried changing the potentiometer to a 10-turn 10kohm but again the same thing. The laser beam stops exiting the tube at around 0 to 4mA. Then as I turn the power up the beam exits and the machine works at around 5mA to 8.5mA and upon 8.5 and above no beam exits the tube but I can the see the plasma grow brighter as I increase the power. Concerning the plasma it wiggles a little around the negative ring especially on higher powers. Any other suggestions are really appreciated.

Take a look inside your laser tube, from the end where the beam exits. If the lens i cracked or dirty.

But, the strange power tells me you have a PSU issue if you checked the bridging and are sure you dont hit the edge anywhere, i would go for a Flyback transformer as a first piece to swap out.

Hi HP

My machine is 1 month old. The first 10 days was the only point. 2 points after 10 days. I bought a new tube and used it successfully. There is no single point problem for 10 days. then again point 2 comes back. Like two commas. What do you think could be breaking the shot? No sleep at night for a long time. I’m tired but I found this blog. I hope you can help. Sorry for my bad english.

Split beam is common problem. There is different causes for it.

When you get 2 points, check with a paper right on the laser tube if the 2 points are created out of the tube – or any of the mirrors.

Problem 1: If you run the machine on very low power the beam can be unstable and split in 2.

Problem 2: Hitting the edge on a mirror or a bad quality mirror can cause 2 or more points/shadows. Put a piece of paper in front of each mirror to see where the double dot is created.

Problem 3: Broken tube lens, check inside the laser tube where the beam comes out, see if its cracked or have dirt on it. Clean it.

Hi HP Persson,

Was wondering if you could advise me.

I have just exchanged and inserted a cohesion3d laserboard, upgrading from a Nano. All the lights on the board are doing what they are supposed to do.

When I use lightburn it goes through all the motions of cutting/engraving, but no laser! When I press the test button on the laser it works fine and the ammeter registers, its just when I run the program.

Truly baffled!

Any help would be greatly appreciated Thanks.

Make sure you have a common ground between the C3D board and the the ground point of your laser machine. And make sure the laser PSU (power supply) and the 24V power supply is also grounded at the same point.

If you you a small 24V “brick type” PSU for the controller, take a cable and put between C3D ground pin (Negative -) and Laser PSU GND pin (Negative -) (any of them) or directly to the ground bolt in the rear of the machine.

See this picture as reference. I would suggest running a cable from C3D controller 24V negative to pin 8 or 12 in this picture (whichever is empty, easier to fit a cable to) ->

I have this solution in all of my machines, no matter what controller it uses.

– 24V PSU is grounded in the controller board – and one cable going back to the ground bolt in the chassis.

– LaserPSU is grounded to the ground bolt in the chassis

– All extra PSU´s (for lights, fans etc) is grounded to the ground bolt in the rear.

They all share the same GND no matter if they are feeded from the same inlet-cable or have separate cables.

HP,

Had a problem with my k40 laser tube arcing after rastering something, went to the cut command and lost laser power quickly over 2 seconds. Lots of arcing. After investigation, I noticed the laser was arcing inside the case. I had previously thought it was arcing outside of the tube because of a small black spot on the backside of the laser tube, but after putting silicon on it, I retried and seen it was arcing from the anode. I added silicon there and now no fire. I had a lot of condensation and everyone acted like that was a big no-no, but its 85+ degrees out and 90% humidity, 15-20C makes my tube condensate like crazy. any advice on my condensation problem? also, would you guess that the laser tube is just bad instead of being the HVT? laser still has movement, just no power.

If it´s arcing the PSU is good, you might kill the HVT with arcing though. I have 120mm computer fans added on each side of my laser tube, one pulling and one pushing on all my machines, it cools down the tube slightly from the radiated heat and moves the dew point further away. Some machines has a hole for longer tubes, put the fan there. You can try with one pushing air in to begin with.

Hi HP, I’m posting here because a friend of mine asked me to fix a faulty K40 laser. Basically when I light up the machine the laser head starts aligning bottom-right instead of up-left and the motherboard seems to work fine: the laser doesn’t fire at all even when I press the test button, no fire, no noise, nothing, even the amperometer seems dead. I’m working on, as my friend says, a new power supply but I did a mess so I’m trying to figure out what is wrong.

Is there a way to test if the flyback transformer is working? Which voltage should go to the flyback? Thank you a lot, you are the only one who can help me 🙂

Alex from Italy.

Homing down and right is probably the end stop no connected or broken, when it doesnt get a signal it goes the opposite direction. Check the end-stops – both of them as they are going wrong direction. The flyback should not be measured at all – it´s 12-16000 volts in that one and you need special meters to measure it properly without dying 🙂 There is a redneck-test, putting the positive lead aprox. 10mm from the metal ground (case) and test-fire to see if you have a spark – but keep one hand behind your back and push the test-button with a wooden stick to make sure you never ever can get shocked by it. I always suggest bying a new flyback instead of doing a test like that, they are like 20-25 USD + shipping from china. You can use this pic to see what´s going where on the power supply -> https://k40laser.se/oldpsulayout/

Perfect, I’ll give a try soon. Thanks for your support and compliments for the site 🙂

Hi Ive been searching high and low and you have identified the problem!

I bridged my p+ and GND on the PSU (type 2) and my laser fired at last.

Now – i dont have a flow controller anywhere on the machine that I can find, so how do i go about fixing it? Or should I install one?

I have nothing in my k+k- port (PSU type2) and my P+ GND (PSU type 2) plugs into P+ and p- on control board.

I have a JK-K3020

please help, ive been trying for days!

If you do not have a flow sensor, you can bridge P+ and GND, just make sure you have water flow before using the machine. If you have the digital panel some connectors will be missing, it test-fires through another pin so it´s ok with missing cables on K+/K-

Thanks for this guide. When I test fire the laser both with the test button and the power supply test button there is a clicking but no laser. Do I need to replace both the tube and the power supply. Which would you suggest to do first? Seems a waste, is there anybody who recycles these?

Without doing a high voltage test its a chance. The tubes doesn´t die quickly, they fade away in 9 of 10 faults with them. But the PSU often dies over a second. I would go with a PSU to start with, or only the flyback transformer.

Thanks, I will do this. You mention elsewhere on this site the Hy t50 PSU..can this be used with the k40 or will it be ‘overpowered’? I have the digital readout – yet to install a mAmmeter.

Hy-T50 will work good on the K40. Just keep a eye on the mA-meter not to over power the tube. I have changed to T50´s in all my machines, one even have a T80.

Ok, I have just ordered one, will let you know if it fixes my machine. Thanks